ZMC460 Motion Controller User Manual V1.5

lower communication rate is, and maximum

of 100m is recommended.

→

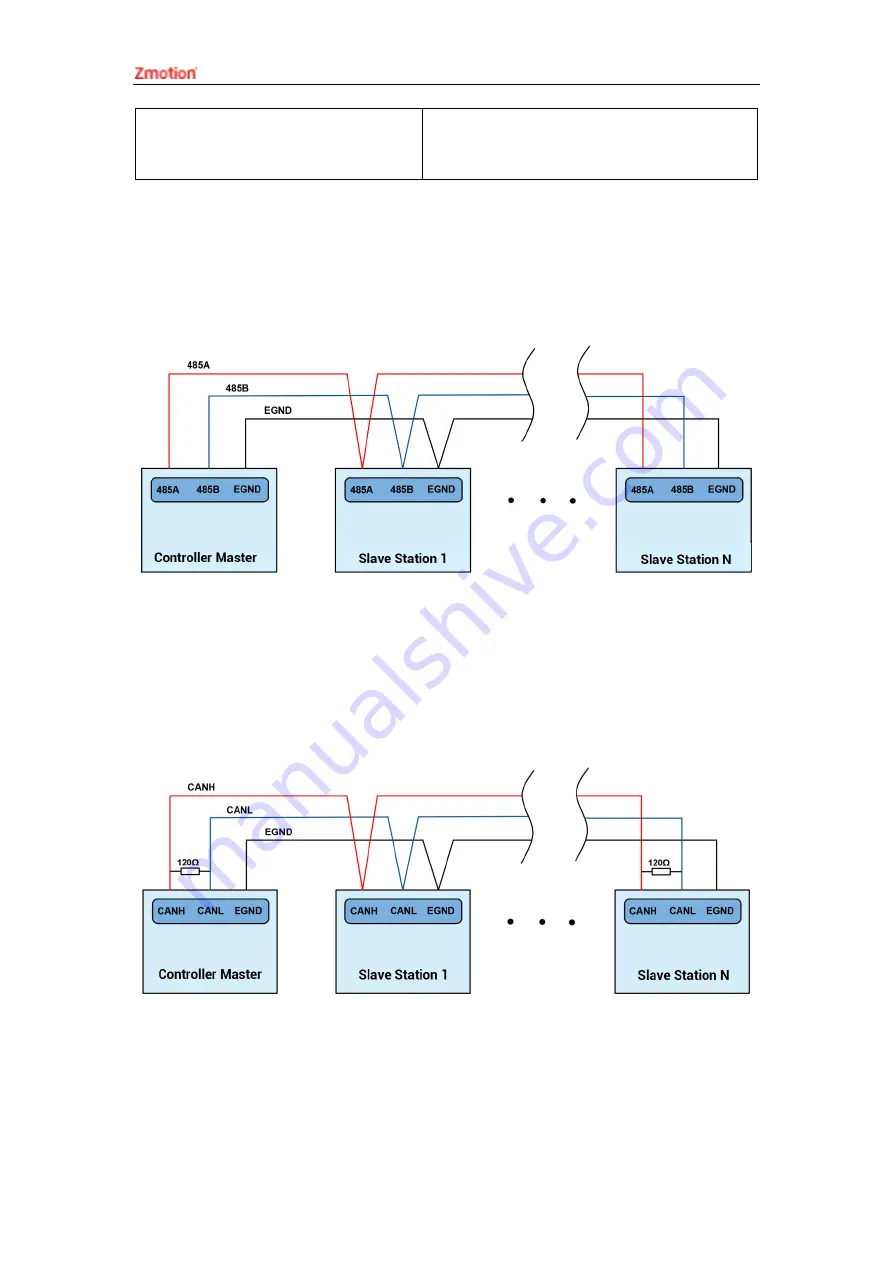

Wiring Reference

Connect 485A and 485B of RS485 to 485A and 485B of the controller correspondingly,

and connect the public ends

“

EGND

”

of RS485 communication parties together.

Connect the CANL and CANH of the standard CAN module to the CANL and CANH of

the other side correspondingly. And public ends of the CAN bus communication both

parties are connected together. In CAN bus left and right sides, connect a 120

Ω

resistor

respectively (please see below graphic).

→

Wiring Notes:

⚫

As above, the daisy chain topology is used for wiring (the star topology structure

cannot be used). When the use environment is ideal and there are no many nodes,

Summary of Contents for ZMC460

Page 1: ......