Page 7

Page 6

EziSalt Saltwater Chlorinator | Installation Manual

Section 2. System Overview

2.1 Contents

Before starting, check that you have the correct

parts as indicated in Table 1. If any parts are

missing or incorrect, please call your local distributor

or technical support at 1300 763 021 for assistance.

2.1.1

Salt Chlorinator System

MENU

OK

BOOST

LOW

SALTS

INFO

EziSalt Saltwater Chlorinator

a. Controller

b. Wall Mount Bracket

c. Wall Mount Screws Ø7 mm (X2)

d. Wall Mount Anchor (X2)

e. Electrolytic Cell

f. Screw Barrel Unions (X2)

g. 40mm Glue On Adapter (X2)

Table 1. Salt Chlorinator System Contents

2.2 Specifications

2.2.1

Salt Chlorinator System

EziSalt 24

EziSalt 40

Nominal chlorine production

24 g/h

40 g/h

Nominal output amps

5.0 A

7.2 A

Required salt level

4000ppm

Power supply voltage

240 VAC - 50 Hz

Electric power

200 W

Protection index

IP43

Flow through the cell

Min. 80 Lpm

Operating water temperature

10°C - 40°C

Table 2. Salt Chlorinator System Specifications

2.3 Dimensions

2.3.1

Controller

MENU

OK

BOOST

LOW

SALTS

INFO

31.5 cm

9.6 cm

36.4 cm

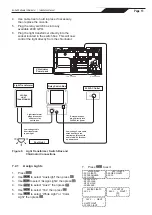

Figure 1. Controller Dimensions

2.3.2

Cell

26 cm

11.5 cm

21.5 cm

8 cm

12 cm

10 cm

Figure 2. Electrolytic Cell Dimensions

2.4 Materials and Tools

2.4.1

Controller

Tools Needed for Installation

• Power Drill

• 7 mm Drill Bit - Hammer Drill Bit

(only necessary to drill into brick or concrete)

• Pencil or Marking Pen

• Flat Head Screwdriver

• Pozidiv Screwdriver

• Small Flathead or Slotted Screwdriver

2.4.2

Cell

Tools Needed for Installation

• PVC Cutter

• PVC Cement

• Pencil or Marking Pen

• Check Valve

• 40 mm PVC Pipe