COMPUTER-CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE

- 44 -

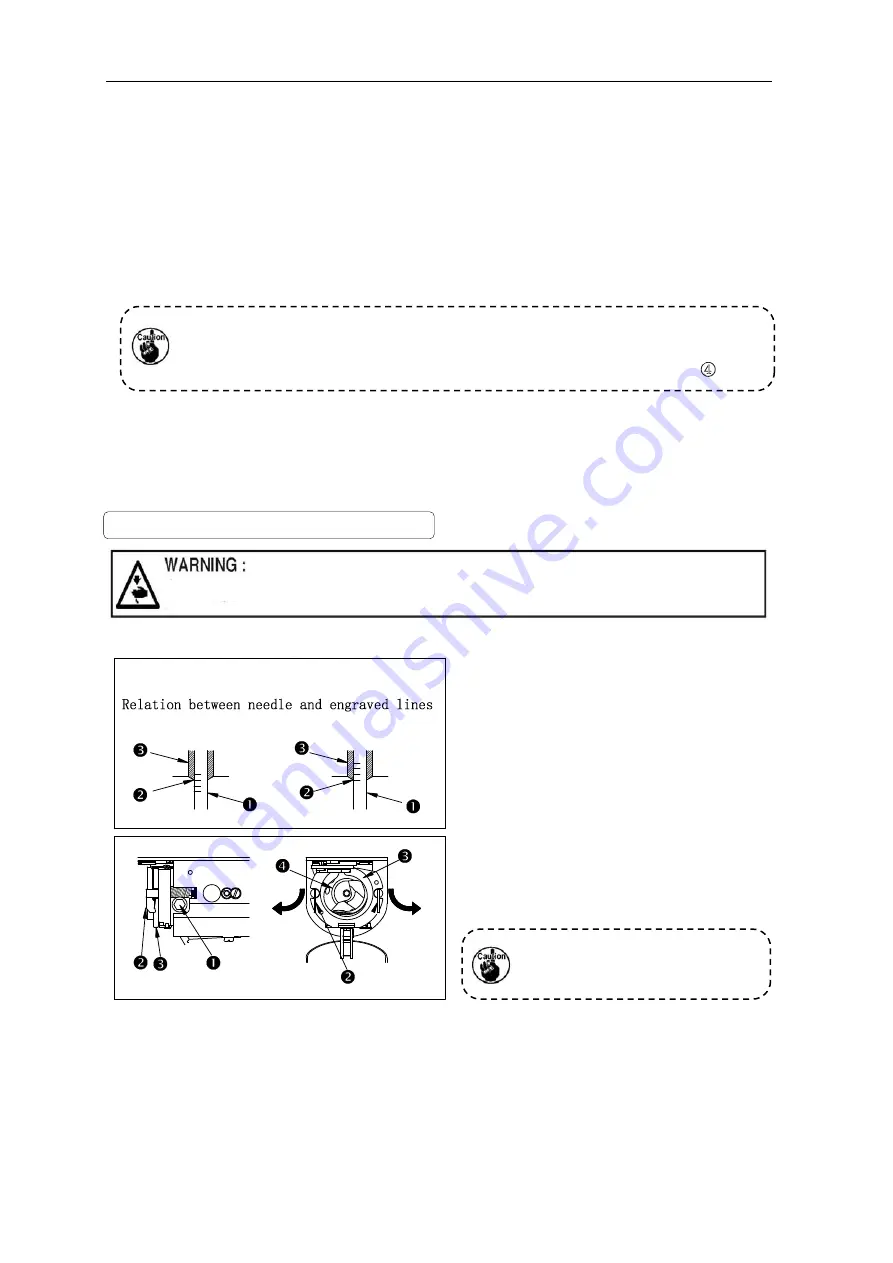

Bring needle bar

①

to the lowest position of its stroke. Loosen needle bar connection

screw

②

and adjust so that upper marker line

④

engraved on the needle bar aligns with the

bottom end of needle bar bushing, lower

③

. For F type only, adjust the needle bar to the

position where it is lowered by 0.8 mm to 1 mm from the center of upper marker line

④

engraved on the needle bar.

2. Adjusting the needle-to-shuttle relation

Turn OFF the power before starting the work so as to prevent

accidents cause by abrupt start of the sewing machine.

After the adjustment, make sure that there is no uneven torque. When stitch

skipping occurs in accordance with the sewing conditions, adjust the height of the

needle bar so as to lower it by 0.5 to 1 mm from the needle bar engraved line

④

.

.

⑴

Turn the hand wheel by hand. When

needle bar

①

has gone up, adjust so that

lower marker line

②

engraved on the needle

bar aligns with the bottom end of the needle

bar bushing

③

, lower.

.

⑵

Loosen setscrew

①

in the driver.

Open inner hook pressers

②

to the

right and left, and remove inner hook

presser

③

.

At this time, be careful not to let

inner hook

④

come off and fall.

Summary of Contents for ZJ1900DSS

Page 6: ...高速电子套结机 2 各部件名称 1 主机的名称 缝纫机机头 送布压脚 线架 操作面板 电源开关 脚踏开关 2 2 1 2 5 3 2 6 2 4 2 7 机架 ...

Page 9: ...高速电子套结机 5 7 电线的连接 脚踏板 操作面板 8 眼睛防护罩的安装 为防止断针飞起弄伤眼睛 请一定安装起来 将附件箱中眼睛防护罩装在机头 如图所示左侧 ...

Page 25: ...高速电子套结机 21 图1 ...

Page 67: ...高速电子套结机 Ⅵ 台板图纸 63 Ⅱ ...

Page 96: ...COMPUTER CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE 25 图1 ...

Page 97: ...6 ...

Page 146: ...COMPUTER CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE 75 Ⅵ DRAWING OF THE TABLE Ⅱ ...