12

The barometric bypass damper is for systems 5 tons or under. It utilizes

a weighted damper blade to maintain constant duct pressure. This

allows for easy installation without the need for electrical power or

wiring. The round barometric damper can be installed in any position. It

is an efficient solution for small system fan capacity control.

SIZING:

When only the smallest zone is calling, the maximum

amount of excess supply air will flow through the bypass damper. To

determine the proper size bypass damper to use, do the following steps:

Step 1: Calculate bypass air volume as follows.

A) Calculate total air volume at 400 CFM

per ton.

B) Calculate air volume of smallest zone in

CFM.

C) Calculate bypass air volume by subtract-

ing the smallest zone air volume from

the total.

(A - B = C)

Step 2: Select damper from sizing table.

Once you have calculated the bypass air volume from Step 1, use the

BAROMETRIC BYPASS SELECTION TABLE. From the table, select the

bypass damper with the CFM rating equal to or greater than the value

calculated in Step 1. For rectangular barometric dampers, use a

ductulator to convert from round to rectangular.

If bypassing more than 2000 CFM, use electronic bypass damper.

Example:

You have a 4 ton system. Your smallest zone will use 500

CFM. The total CFM is 1600 CFM (400 * 4). Your bypass CFM is 1100

(1600 - 500). From the table, you determine that a 12” bypass damper

is needed.

Do not use the barometric bypass in any system over 5 tons.

For systems over 5 tons, or to bypass more than 2000 CFM, use the

electronic bypass.

RECTANGULAR & ROUND

BAROMETRIC BYPASS

BYPASS DAMPERS – BAROMETRIC

AIRFLOW

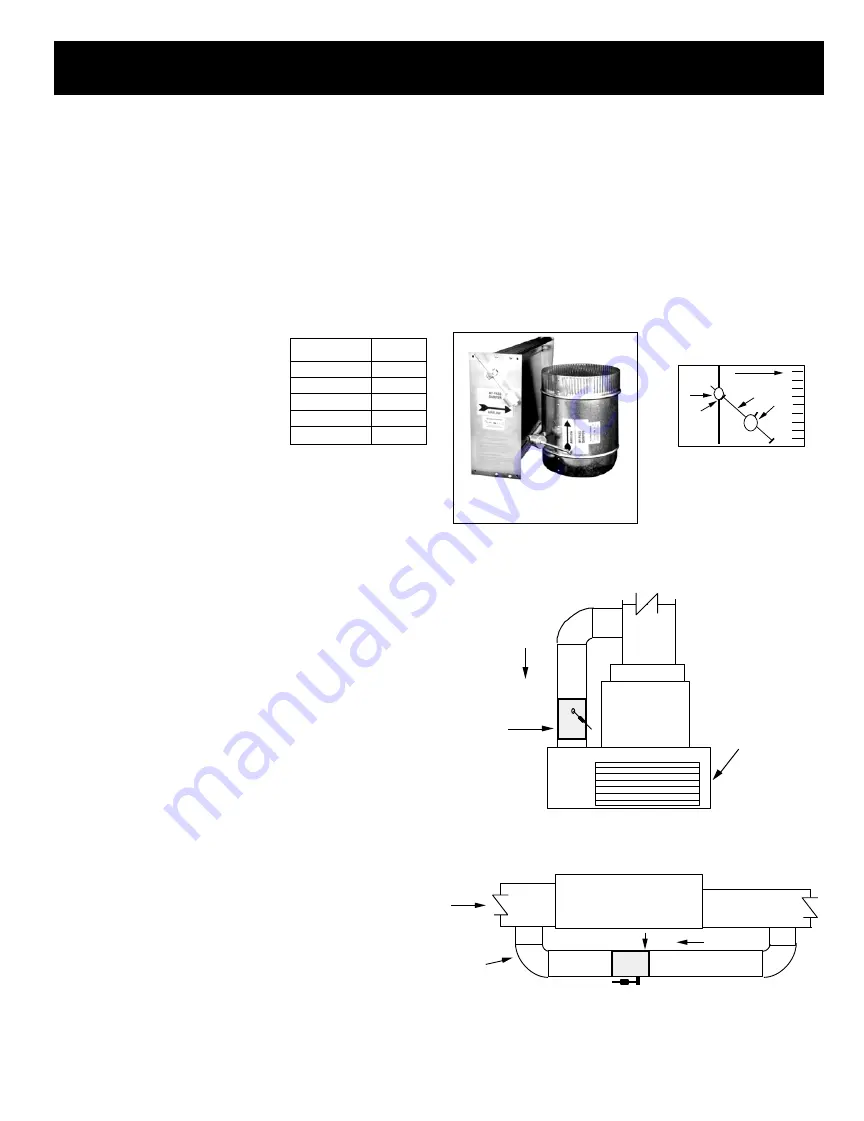

1

2

4

3

1. Damper Shaft

2. Lock Nut

3. Lever Arm

4. Counter Weight

BAROMETRIC BYPASS

DAMPER

Diameter

CFM

9”

650

10”

800

12”

1200

14”

1600

16”

2000

BAROMETRIC BYPASS

SELECTION TABLE

INSTALLATION

The round barometric bypass damper can be installed in any position.

This damper is factory set for horizontal installation and can be field

modified for vertical installation. Do not run speed screws into damper

housing. Screws may interfere with damper travel. Make sure counter

weight is not obstructed in any way.

a)

Install the bypass damper between the supply and return

plenums of the unit. It must be the first tap off the supply plenum.

b)

Be sure the air flows through the damper in the proper direction

as indicated by the arrow on the damper. Airflow is always

from supply to return plenum. Be certain the damper shaft

is horizontal.

c) Loosen counter weight with Allen wrench.

d)

Loosen lever arm from damper shaft and allow to hang straight

down.

e)

Fully close damper by grabbing damper shaft on side attached

to lever arm and turning clockwise until it stops.

f)

While holding the damper fully closed, rotate the lever arm a

little to the right (facing the damper) and then screw in to

tighten to the damper shaft. Then tighten lock nut.

g)

Be sure the damper is being held closed by the counter weight.

Proceed to setup

.

AIRFLOW

AIRFLOW

RETURN

BAROMETRIC

BYPASS

HORIZONTAL APPLICATION

SHEET METAL

PIPE

SUPPLY

PLENUM

A/C UNIT

OR

FURNACE

A/C UNIT

OR

FURNACE

RETURN

AIR

PLATFORM

BAROMETRIC

BYPASS

RETURN AIR GRILLE

AIRFLOW

SUPPLY

PLENUM

VERTICAL APPLICATION