22

INTEGRATED PRESSURE CONTROL

4.

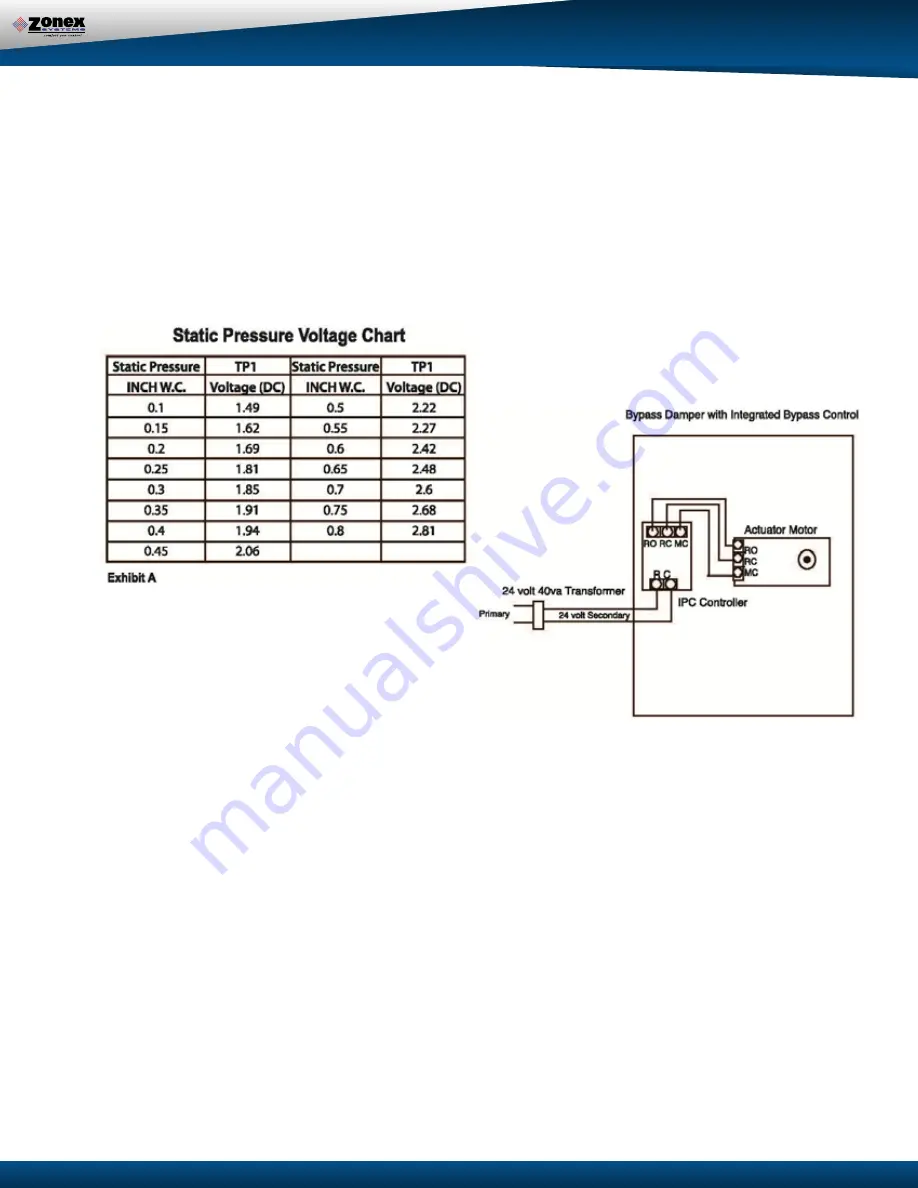

Static Pressure Option:

The Integrated Pressure

Control Board can be field configured for specified

static pressure using a multi meter and the static

pressure – voltage chart.

(Exhibit A).

This chart

shows voltage (DC) to inches of W.C. (static

pressure) relationship. Use a multi meter set on

VDC and place the leads on the “C” terminal and

“TP1” (test point one) next to the potentiometer.

The Voltage reading translates to inches of W.C.

Note # 1:

To open all dampers, it may be necessary

to remove Y outputs to unit on the zone control board

and to make full cool calls on all thermostats. This will

modulate dampers fully open and lock out compressor.

BYPASS CHECKOUT FOR STATIC PRESSURE

CONTROLLER

1. Make cool call at the zone thermostat of the

smallest zone.

2. Verify all zone dampers are closed except for

calling zone.

3. Verify noise at zone registers is not excessive.

Adjust the Integrated Pressure Control LEFT to

lower noise (airflow) or RIGHT to increase airflow

until too noisy.

BYPASS DAMPER WIRING DIAGRAM

WITH INTEGRATED BYPASS CONTROL

RECTANGULAR HEAVY DUTY ZONE DAMPERS

(STCD W x H)

Zonex Systems rectangular heavy duty dampers are recommend-

ed for systems 7.5 tons or larger with a maximum differential static

pressure of 1.75”. These are power open, power close dampers

made of 20 gauge “snap-lock” steel frame with S and drive duct

connections. Allow a 16” gap in the duct for the damper. Formed

steel blade stops incorporate a gasket for quiet operation and

improved structural rigidity. Rectangular dampers under 10” in

height incorporate a single blade design. Dampers 10” or over use

opposed blade design. Power consumption is 2VA. The motors are

designed for continuous full stall operation. Special winding and

heavy duty gearing provide for long motor life.