10

Installation

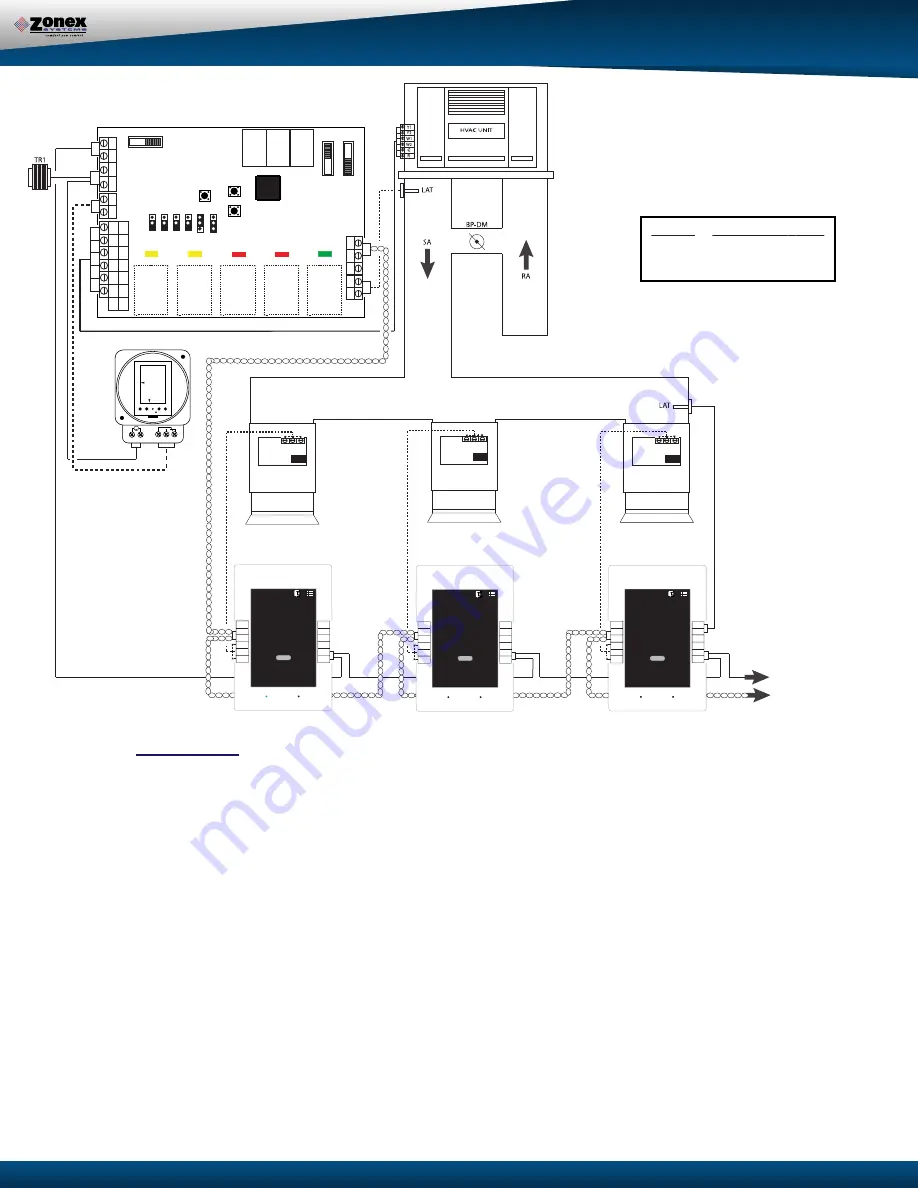

Wiring

All 24-volt and communication wiring connections are made to terminal blocks on the thermostat

sub-base. The communication terminal block (A/B / A/B) is designed as a junction for

22 ga tinned copper, twisted pair communications cable. The cable should be daisy

thermostat to thermostat (use Belden 8740 or Zonex supplied equal).

1. Install the thermostat sub-base on an interior wall away from direct sunlight, supply air currents,

or any heat generating source. Mounting screws and anchors are provided. The sub-base

may be installed on a horizontal 2x4 electrical box.

2. Connect the control wires from the EzTouch’s TR1 & TR2, to the

GEN II

controller TR1 & TR2

(

A

). Verify TR1 & TR2 polarity is the same on each thermostat (18 ga Thermostat wire)

.

3. On the EzTouch, connect the damper output wires from MC, RC and RO to the actuator

motor terminals.

4. Connect the A / B communication wires on the left hand terminal block; there are 2 sets of

A / B terminals to make the daisy chain wiring easier.

NOTE: The communication wire must be twisted pair Belden 8740, 8450 (shielded), 82442

(plenum rated) or Zonex supplied equal.

ZONE THERMOSTAT - EzTouch

Power Communication

R = TR1

RX = B

C = TR2 TX = A

Terminal Connections

DAISY CHAIN 24VAC AND

DATALINK CABLE (BELDEN 8740)

TO ALL ZONE EZTOUCH’S

EXPANDABLE TO 17 ZONES

chained from

two sets of

When the GEN II controller is powered up, the total number of addressed thermostats (EzTouchs) are

determined and verified on the display. This confirms the controller is communicating with all thermostats

in the system. If there are no active heat or cool calls detected, the supply dampers will modulate to 40%

open for ventilation mode. The system blower operation can be configured for constant ON or intermittent

Auto. The controllers are shipped from the factory for Auto fan.

The GEN II systems can be field configured for adjustable time based opposing call changeover, vote

based majority changeover, or priority vote changeover by thermostat assignment. The GEN II controller

is shipped from the factory for 10-minute opposing call changeover. The GEN II controller “polls” the

thermostats once per minute to determine the thermostat demand status for heat and cool. The heat and

cool changeover functions will operate by the type of changeover selected on the controller. When the

GEN II controller changes modes, a 5-minute purge cycle is initiated before the changeover is completed.

On active heat or cool calls, the non-calling zones will modulate to the closed position. When the last

calling zone is satisfied in either heat or cool mode, the GEN II controller terminates the HVAC outputs

after the next “poll” and the blower output will be de-energized (unless controller is configured for constant

fan) for a 5-minute purge cycle. During the purge cycle no heat or cool calls are recognized.

When the system is in the heating mode and calls for cooling are received, an opposing call timer strategy

operates. This timer is adjustable from 10 - 30 minutes. The factory default is 10 minutes. At the end of

the selected time period, if the opposing call is 3° away from set point, heating is turned off. After a 5-min-

ute purge mode, Cooling is turned on until the cool call is satisfied. If necessary, GEN II will return to the

heating mode, If all calls have been satisfied, dampers will modulate to the 40% open position for ventila-

tion. If the opposing zone strategy is not desired, this feature may be disabled.

This mode may be enhanced by adding Priority votes to each thermostat in the system, thereby weighting

certain zones more than others. This Priority mode allows you to select 0, 1, or 2 additional votes for a

thermostat that has unusual loads, like a conference room.

Minimum / Maximum damper positions can be set to provide ventilation. Each thermostat has Auxiliary

contacts that support and control a supplemental heat source i.e., baseboard, reheat, or hot water coil, to

meet the temperature requirements of any commercial application.

MODULATING DAMPER

DM-1

MODULATING DAMPER

DM-3

MODULATING DAMPER

DM-2

MC

RC

RO

MC

RC

RO

MC

RC

RO

7 2

SET

DN

UP

S

S

B

A

C1

GEN II-VVT

ON

AUTO

TIME/TMP

TIME

EH

O/B

HP

PRI

NIGHT

DA

Y

UNLOCK LOCK

OFF ON

G

W2

W1

Y2

Y1

TC

TC

TR1

TR2

TR2

TR1

Y1

Y2

W1

W2

G

R

HP

GE

O/B

R

Y1

Y2

G

W2

0 2 4 6 8 10 12

14

16

18

20

22

24

Mo

Tu

We

Th

Fr

Sa

Su

+1h

OVR AUTO

_

+

Mode

Menu OK

11:25

AM

1 2 3 4 5

M

GCLK

OUT

IN

MC

RO

RC

A

B

GND

AUX

DS

COM

DS

TR1

TR2

T-1

MC

RO

RC

A

B

GND

AUX

DS

COM

DS

TR1

TR2

T-2

MC

RO

RC

A

B

GND

T-3

AUX

DS

COM

DS

TR1

TR2

Optional Duct Temperature monitoring

(LAT sensor is not included)

24VAC

100VA