41

The following applies to the

101CAPGE,

CAPL-2,

CAPL-4 and

SYCAP Setpoints:

There are two cut-out setpoints, one for heat and one for cool. The

digital display normally displays the leaving air temperature of the

HVAC/heat pump unit. By pressing the UP and DN buttons, the setpoints

can be viewed and changed.

Cool Setpoint

– To read the cool cut-out setpoint, press the DN button

until “C” appears and then release. The number that follows is the cool

cut-out setpoint. After a couple of seconds the leaving air temperature will

be redisplayed. To change the setpoint, press the bottom or down button

until the “C” is displayed, then immediately after the setpoint is displayed

press and hold the UP/DN button till setpoint is at the desired value.

Heat Setpoint

– To read the heat cut-out setpoint, press the UP button

until “H” appears and then release. The number that follows is the heat

cut-out setpoint. After a couple of seconds the leaving air temperature

will be redisplayed. To change the setpoint, press the top or up button

until the “H” is displayed, then immediately after the setpoint is displayed

press and hold the UP/DN button till setpoint is at the desired value.

Auxiliary Heat Setpoint

– For the SYCAP only, to read the auxiliary

heat setpoint, press the UP and DN buttons simultaneously until “E”

appears and then release. The number that follows is the auxiliary heat

setpoint. After a couple of seconds the leaving air temperature will be

redisplayed. To change the setpoint, immediately after the setpoint is displayed

press and hold the UP/DN button till the setpoint is at the desired value.

CALIBRATION

The digital display normally displays the leaving air temperature of the

internal thermometer. This thermometer is factory calibrated. If calibration

is ever required, turn the Thermometer Calibrator clockwise to lower the

temperature. Turn counterclockwise to raise.

CAPACITY CONTROLLERS – SETPOINTS, CALIBRATION

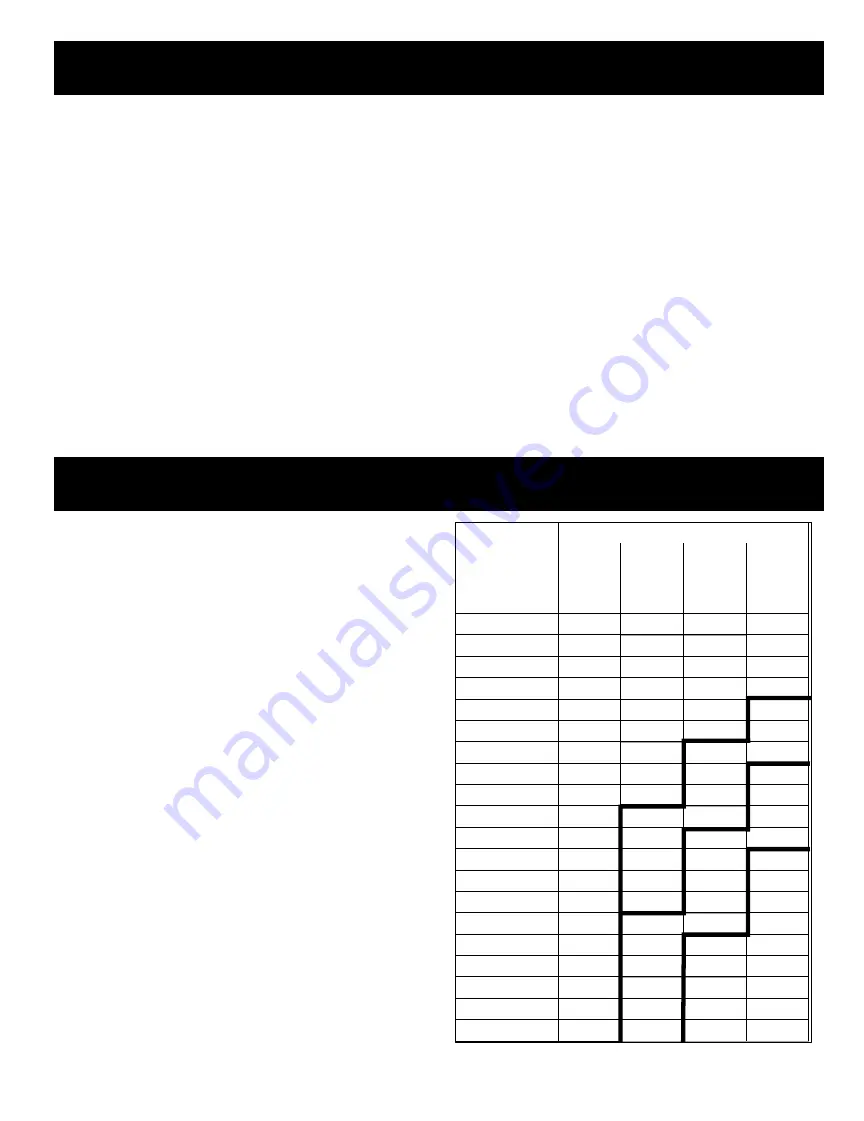

FIVE WIRE LINK

Zonex Systems’s patented Five Wire Link is one of the most important ele-

ments of the System 1000/2000 zoning system. Extra care should be made

to ensure the wiring is done correctly. The color code must be strictly fol-

lowed. Ensure the stripped wire leads are not touching each other at the ter-

minal blocks. If putting two wires into one terminal block, use the same

gauge wire for both and ensure they are seated properly.

You must ensure the wire is sized properly to match the power needs of

the number of dampers installed. The more dampers used, the greater the

current draw and the greater the voltage loss on the Five Wire Link. If too

much voltage is lost on the Five Wire Link, there will not be enough

voltage at the zone dampers to properly operate them. To ensure the

correct wire size, use the following table. Select the row matching the

number of zone dampers you have. Move across horizontally to the

column that matches the distance from the System Controller to the

farthest damper. Use the wire size specified at the row/column

intersection.

To reduce wire size, you can run more than one Five Wire Link Daisy Chain.

Example: If you have 10 dampers, and the maximum distance is 200 feet,

you would need 12 GA wire. If instead, you used two Five Wire Links with

5 dampers on each, you would now only need 18 GA wire for each daisy

chain. Multiple daisy chains are wired color to color at the System

Controller.

NOTE: Never use less than 18 GA wire on the 5 Wire Link.

WIRE LENGTH

NUMBER OF

ZONE

DAMPERS

50'

100'

150'

200'

1

18 GA

18 GA

18 GA

18 GA

2

18 GA

18 GA

18 GA

18 GA

3

18 GA

18 GA

18 GA

18 GA

4

18 GA

18 GA

18 GA

18 GA

5

18 GA

18 GA

18 GA

18 GA

6

18 GA

18 GA

18 GA

16 GA

7

18 GA

18 GA

18 GA

16 GA

8

18 GA

18 GA

16 GA

16 GA

9

18 GA

18 GA

16 GA

14 GA

10

18 GA

18 GA

16 GA

14 GA

11

18 GA

16 GA

16 GA

14 GA

12

18 GA

16 GA

14 GA

14 GA

13

18 GA

16 GA

14 GA

12 GA

14

18 GA

16 GA

14 GA

12 GA

15

18 GA

16 GA

14 GA

12 GA

16

18 GA

14 GA

14 GA

12 GA

17

18 GA

14 GA

12 GA

12 GA

18

18 GA

14 GA

12 GA

12 GA

19

18 GA

14 GA

12 GA

12 GA

20

18 GA

14 GA

12 GA

12 GA