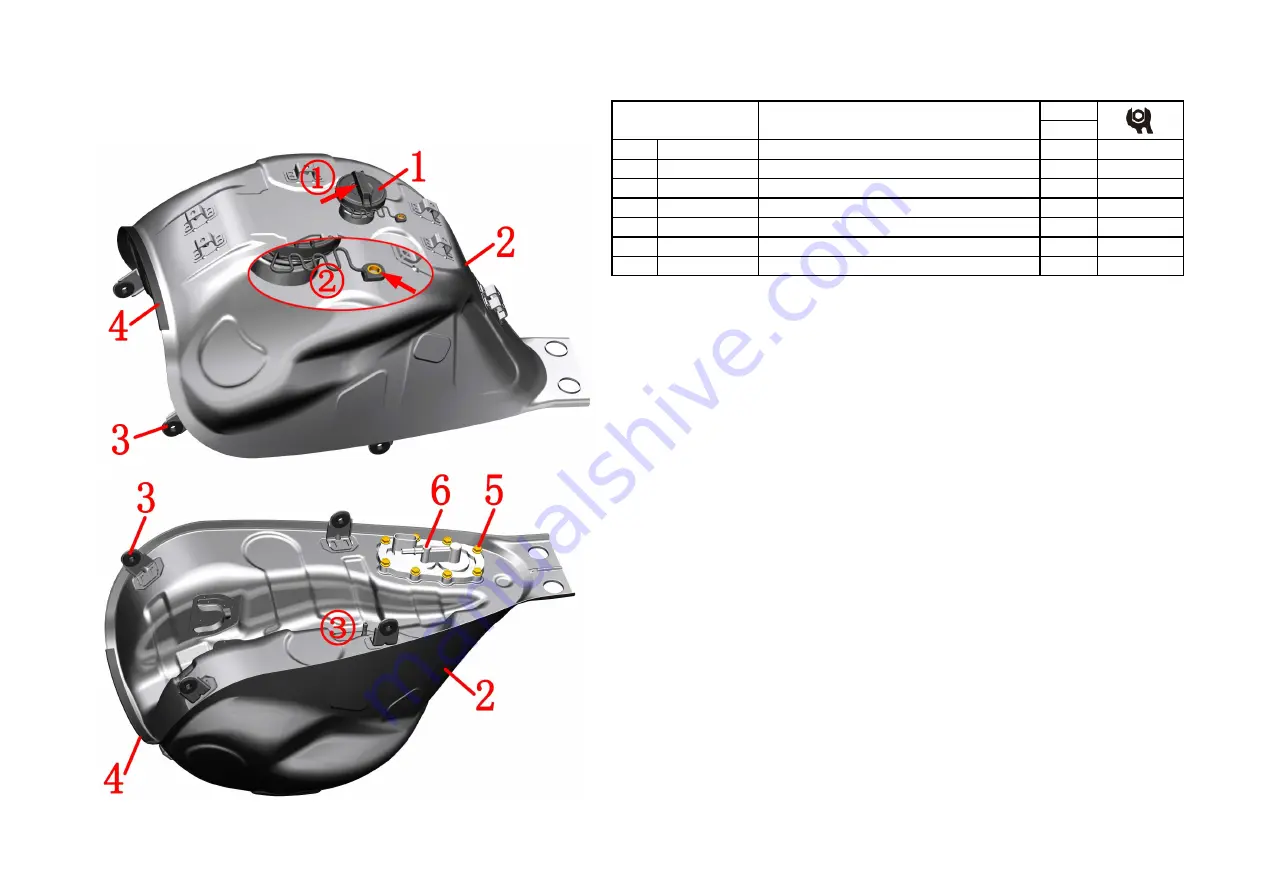

10、TANK LINER COMPONENT

94

CHK

ADJ

NO.

PART NO.

PART NAME

QTY

CAUTION

1

1224100-033000 ZT250-S threaded fuel tank cap

1

2

4034200-009000 ZT310-T fuel tank liner

1

3

1244100-002000 ZT250-S side cover round glue

4

4

1240300-021000 HJ125-6 shroud glass strip (1.5m)

0.17

5

1250105-137093 GB5789M6×16 (environmental color)

8

6

1050954-031000 T02 built-in fuel pump

-

ZT310T

1

PROCEDURE:

●

Fuel tank cap

Pinch

①

by hand to remove the fuel tank cap (1) counterclockwise. Be careful not to pull the nylon cord

②

hard.The newly purchased fuel tank cap needs to be removed from the bushing at the arrow indication to be used

in the large fuel tank state, otherwise the expansion screw cannot be inserted into the fixed nylon cord.

●

Adhesive strip

Pull the strip (4) off the end of the strip by hand.

●

Side cover round glue

Remove the side cover round rubber (3) from the tank liner (2).

●

Fuel pump

After the tank liner component is placed upside down, remove the bolts (5) with a sleeve.

When the fuel pump (6) is removed, the float connecting rod cannot be bent or bent to avoid inaccurate oil

display.

CAUTION:

●

It is recommended to use the oil pump to pump out the fuel or consume the fuel before disassembling the tank

component.

●

Fireworks, answering or dialing should be strictly prohibited near the car-breaking site to prevent accidents.

●

Reverse the fuel tank inner component When removing the fuel pump, be sure to check if the fuel tank cap has

been tightened to prevent the remaining fuel from overflowing from the fuel tank port; the vent pipe

④

may have

a small amount of fuel overflow when the fuel tank cap is turned back.

●

When reassembling the fuel pump, be sure to clean the joint surface of the fuel pump sealant and the tank

liner. When locking the bolt, the position should be locked to ensure uniform deformation of the seal gasket.

●

When assembling the fuel tank cap, be careful to rotate

①

to the position shown in the figure. In other

positions, it may interfere with the process clip of the fuel tank cover.

Fig. 6 Tank liner component

Tank liner component

(

Big fuel tank

)