Tips for cutting

140

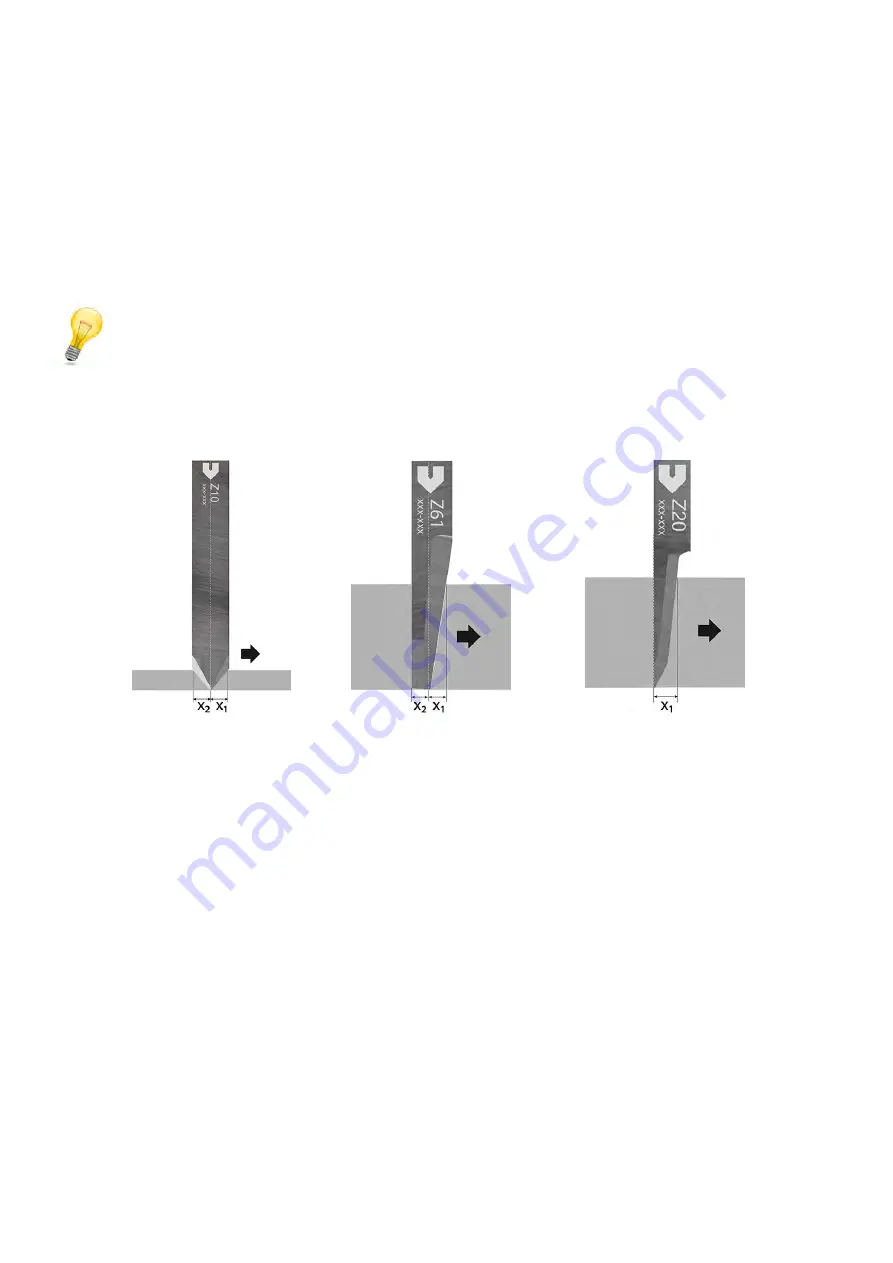

5.2.3.4 Overcut

The pre-cut x

1

is the distance from the centre of the axis of rotation to the first point where the cutting

edge cuts the material surface in the direction of travel. The post-cut x

2

is the measurement from the

centre of the axis of rotation to the last point where the cutting edge cuts the material surface.

The cutting angle has the greatest influence on processing quality. A narrower cutting angle may

enable a faster processing speed, but it also produces a greater overcut. A narrower cutting angle can

be used for paths that include large curves and long straight sections.

Tip:

The overcut distorts the cutting paths. For cuts with a low margin of error, Zünd recommends

choosing a knife with a lower overcut. Overcut information can be found in the additional

specifications for each knife.

Drag knife

Oscillating knife, flat

Oscillating knife, pointed

5.2.3.4.1 Calculating the overcut

Depending on the cutting depth, the blade geometry will produce a different level of overcut. This

chapter explains how to calculate your overcut based on the blade you are using and the material you

are cutting. The Z20 pointed oscillating knife and Z11 drag knife are used as examples here.

The cutting depth TM is made up of the material thickness t and the set depth z. Insert these values

into the formula as they are listed in the product description for each blade. The result will be the pre-

cut/post-cut in mm.

Summary of Contents for S3 M-1200

Page 1: ...Operating Manual S3 Digital Cutter ...

Page 5: ...Contents 5 8 Modules 209 9 Material handling 211 10 Additional specifications 213 ...

Page 6: ...Contents 6 ...

Page 10: ...Introduction 10 ...

Page 14: ...Product description 14 2 5 Cutter overview ...

Page 38: ...Product description 38 ...

Page 64: ...Safety 64 ...

Page 90: ...Controls and operation 90 4 13 3 Inserting replacing the module ...

Page 103: ...Controls and operation 103 Plastic perforated plate Adjustable vacuum range Leather no ...

Page 134: ...Controls and operation 134 ...

Page 155: ...Tips for cutting 155 5 6 2 Calculation of maximum speed for EOT POT Z16 Z42 ...

Page 207: ...Tools 207 7 Tools ...

Page 208: ...Tools 208 ...

Page 209: ...Modules 209 8 Modules ...

Page 210: ...Modules 210 ...

Page 211: ...Material handling 211 9 Material handling ...

Page 212: ...Material handling 212 ...

Page 213: ...Additional specifications 213 10 Additional specifications ...

Page 214: ...Additional specifications 214 ...