Tips for cutting

157

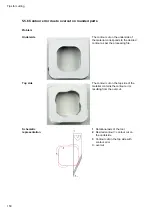

Material accumulation in corners

The angle from which the tool is

raised during change of direction is

set too high. As a result the change of

direction is performed in the material.

Check setting of lift-up angle (may be too

large – reduce)

1-1-1-3-5-1 Auto

lift-up angle

Poor quality cutting edges

Wrong tool is used to process the

material

Select a different tool. It is often a good

idea to use an oscillating tool (EOT or

POT).

-

Worn blade

Insert new blade. Ordering information

can be found in the Zünd accessories

catalog.

-

The processing speed is too fast.

Reduction of the processing speed.

1-1-1-3-2 Speed

Material cover layer is damaged

Wrong tool is used to process the

material

Select a different tool. It is often a good

idea to use an oscillating tool (EOT or

POT).

-

Worn blade

Insert new blade. Ordering information

can be found in the Zünd accessories

catalog.

-

The processing speed is too fast.

Reduction of the processing speed.

1-1-1-3-2 Speed

Material is perforated.

Wrong blade used in relation to the

speed requirement (pointed instead of

flat horizontal blade).

Select a blade which is appropriate to the

material, material thickness and cutting

contour. For help with selecting the

right one, refer to the Zünd accessories

catalog.

-

The processing speed is too fast.

Reduction of the feed speed.

1-1-1-3-2 Speed

Set depth too low

Set greater set depth

1-1-1-2-6 Z-

offset

"continuous path" set incorrectly.

Prescribed maximum speed

exceeded.

Switch on "continuous path"

1-1-1-3-1-6

Continuous

Path

Dimensional stability is wrong

Blade incorrectly clamped.

Check the mechanical blade position.

-

Zoom factor is not "1"

Set zoom factor X to "1"

2-2-1 X scale

Summary of Contents for S3 M-1200

Page 1: ...Operating Manual S3 Digital Cutter ...

Page 5: ...Contents 5 8 Modules 209 9 Material handling 211 10 Additional specifications 213 ...

Page 6: ...Contents 6 ...

Page 10: ...Introduction 10 ...

Page 14: ...Product description 14 2 5 Cutter overview ...

Page 38: ...Product description 38 ...

Page 64: ...Safety 64 ...

Page 90: ...Controls and operation 90 4 13 3 Inserting replacing the module ...

Page 103: ...Controls and operation 103 Plastic perforated plate Adjustable vacuum range Leather no ...

Page 134: ...Controls and operation 134 ...

Page 155: ...Tips for cutting 155 5 6 2 Calculation of maximum speed for EOT POT Z16 Z42 ...

Page 207: ...Tools 207 7 Tools ...

Page 208: ...Tools 208 ...

Page 209: ...Modules 209 8 Modules ...

Page 210: ...Modules 210 ...

Page 211: ...Material handling 211 9 Material handling ...

Page 212: ...Material handling 212 ...

Page 213: ...Additional specifications 213 10 Additional specifications ...

Page 214: ...Additional specifications 214 ...