FV808 Rev. A 09/07/21

Page 10

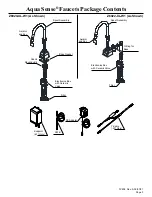

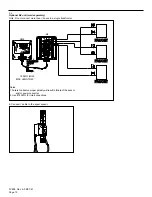

2. Connect sensor inline connector to electronics module and

hydrogenerator.

3. Open battery module using supplied Allen wrench and install

supplied alkaline batteries in the electronics module.

Z6950 Series

Battery Powered

Sensor Faucet

MADE IN XXX Form No. FV559

Electronics Module Installation Instructions (-HYD)

5. Ensure sink is clear of tools/debris and is in normal operating

condition. Remove protective film from sensor lens if needed.

6. Turn on water supply(ies).

4. Tighten electronics module assembly with hydrogenerator to

shank and connect water line(s).

1.

Connect hydrogenerator(A) downstream of electronics

module(B) and filter(C) to bottom of electronics module.

B

A

C

7. Connect sensor inline connector to sensor cable from spout.