12

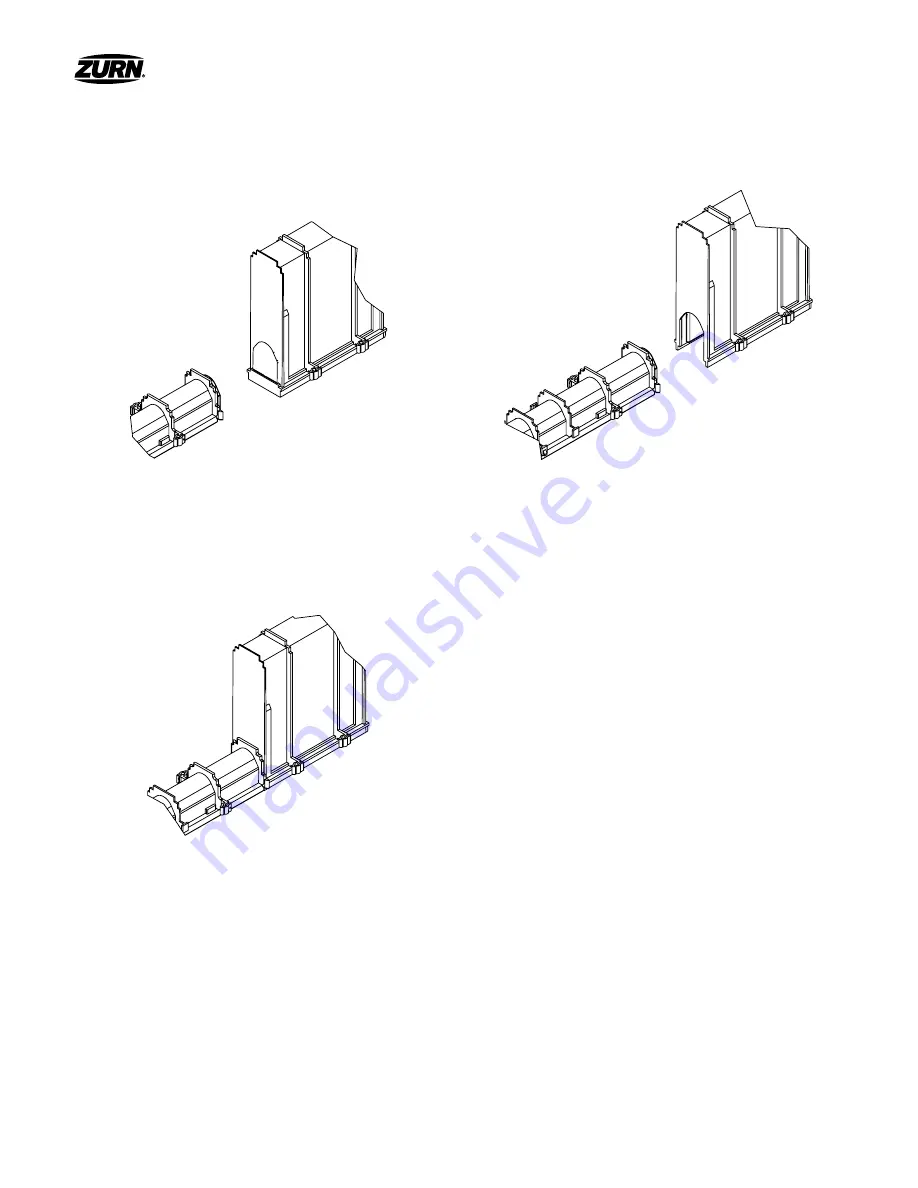

Z886 PERMA-TRENCH

INSTALLATION INSTRUCTIONS

Z886 Catch Basins

FULL CHANNEL INSTALL

1

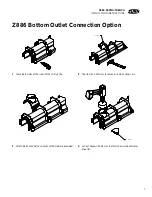

To make connection to a basin, invert the basin and

channel and trace the outline of the channel onto the

basin. This should be done for all sizes of basins. Then

remove the mechanical joint.

2

Cutting the hole in the basin can be easily accomplished

with the use of a hand saw or power reciprocating saw.

Cut out the material inside of the traced area.

3

Slide the male end of the channel into the basin attaching

them together with the supplied hardware and silicone

caulk or construction adhesive through the ribbing.