# Meaning

Description

1. No device communication

No device physically connected OR message CRC error

2. Wrong device connected

The connected device Slave ID is NOT the right one

3. Device not initialised

The connected device has not been correctly initialised at the

end of manufacturing (where applicable - see device dependent sections)

4. Internal configuration map error Software configuration tables bug

5. Wrong parameter number

The requested parameter number doesn’t exist (only for writing operation)

6. Wrong parameter value

The parameter value is not allowed (only for writing operation)

7. Command not executed

The command is correctly received by the EP010 but it’s not possible to

send it to the device (e.g. the device is not connected).

8. Watchdog fault

Start-up diagnostics

9. Modbus UART fault

Start-up diagnostics

10. RS 485 driver fault

Start-up diagnostics

Table 5.Diagnostic codes

6 Diagnostic & Troubleshooting

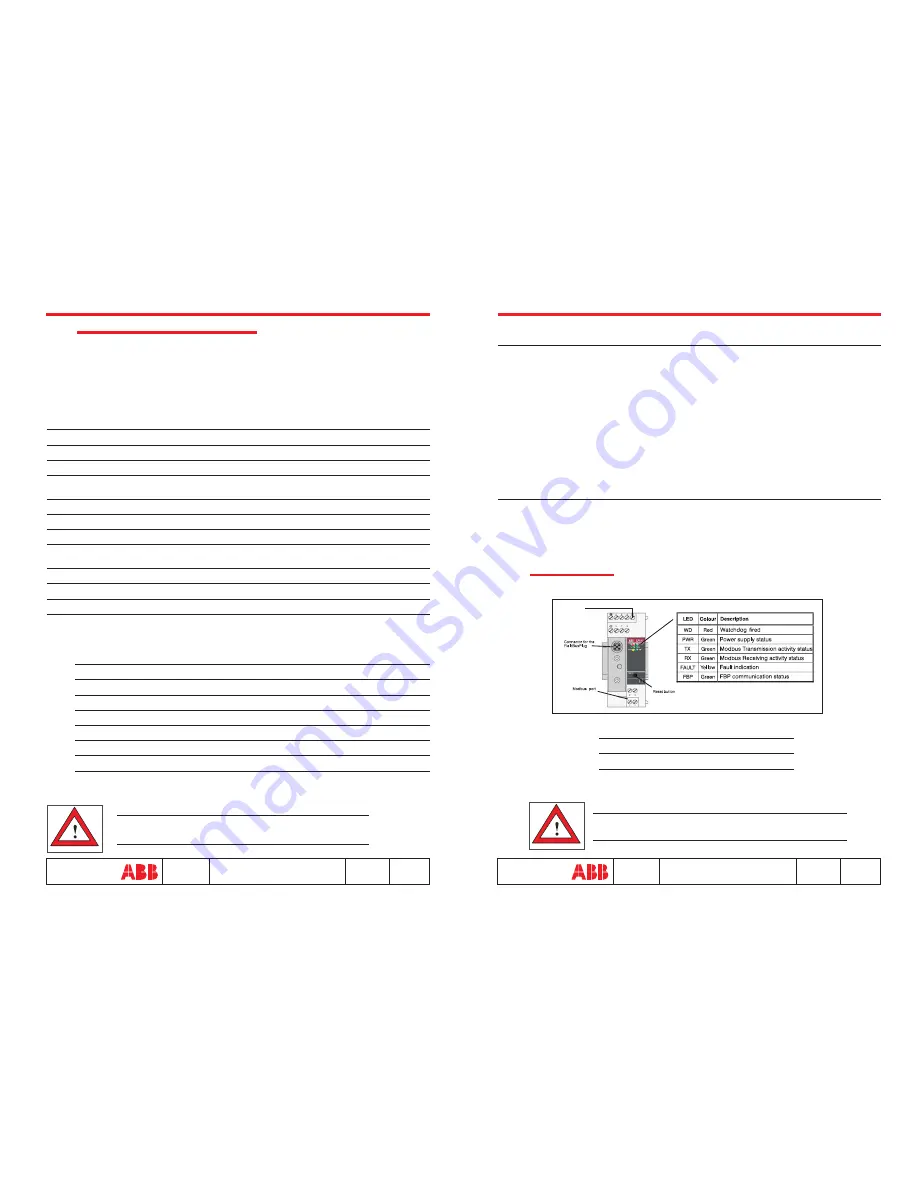

6.1 Diagnostic

There are two different type of diagnostic information:

1. local, by FAULT LED flashing

2. remote, by diagnostic information available from FBP

When the FAULT LED flashes at least one of the following conditions is verified

6.2 Troubleshooting

Depending on the status and behaviour of the LEDs it’s possible to get locally some

information:

#

Symptom

Diagnosis

1. Some or all LEDs still ON after start-up sequence

SW/HW bug

2. - TX LED flashes (very fast) and

No response from the device

- FAULT LED flashes at 2 Hz and

- FBP LED flashes at 2 Hz

3. FAULT LED flashes at 2 Hz

- Previously detected fault and

- no communication with the FBP

Table 6. Troubleshooting

NOTE: the PWR LED is always ON if EP010 is powered.

1SDH000509R0001

L3116

E P 0 1 0

ABB SACE

N° Pag.

4/4

EP010: INSTALLATION, USE AND DISINSTALLATION PROCEDURES

INDEX

FIGURES INDEX

INSTALLATION INSTRUCTIONS ............ 1 Figure 1. Terminals, indicators and operating

elements on the front plate ............................. 1

Figure 2. Dimensions for mounting ................. 2

1 DESCRIPTION .................................... 2

2 Replacement of a defective EP010 ...... 2 TABLES INDEX

3 Mechanical data .................................. 2 Table 1. Modbus port terminals ...................... 1

4 Start-up ............................................... 3 Table 2. Device communication parameters ...2

5 Run state ............................................. 3 Table 3. Start-up LEDs sequence ................... 3

6 Diagnostics & Troubleshooting ............ 4 Table 4. Normal LEDs behaviour .................... 3

6.1 Diagnostic .......................................... 4 Table 5. Diagnostic codes .............................. 4

6.2 Troubleshooting .................................. 4 Table 6. Troubleshooting .................................4

Installation Instructions

This document describes the installation, use and disinstallation procedures of EP010

program further named as program.

For more information see document. n.1SDH000510R0001.

1 Description

Figure 1. Terminals, indicators and operating elements on the front plate

Table 1. Modbus port terminals

TERMINAL NAME

MODBUS CABLE

L (left)

A

1 (right)

B

1SDH000509R0001

L3116

E P 0 1 0

ABB SACE

N° Pag.

1/4

Please note that NO communication between FBP and EP010 is active if there

is a failure on the relevant serial channel (UART).

Total length of the Modbus cable from EP010 to connected device has to

be less or equal to 1 m.

Protective

Earth