Absco Industries

Assembly Instruction Manual

ABSCO WORKSHOP SHED

MODEL: 45302WK

4.48mW x 3.00mD x 2.10mH

Model: 45302WK

17/03/21

1.2

1

DOWNLOAD

OUR APP FOR

ASSEMBLY

VIDEOS

LEAVE A REVIEW

Tell us about your experience and

receive a $20 Coles Gift Card.

Visit

www.abscosheds.com.au/review

AU: 1800 029 701

NZ: 0800 466 444

admin@absco.com.au

www.abscosheds.com.au

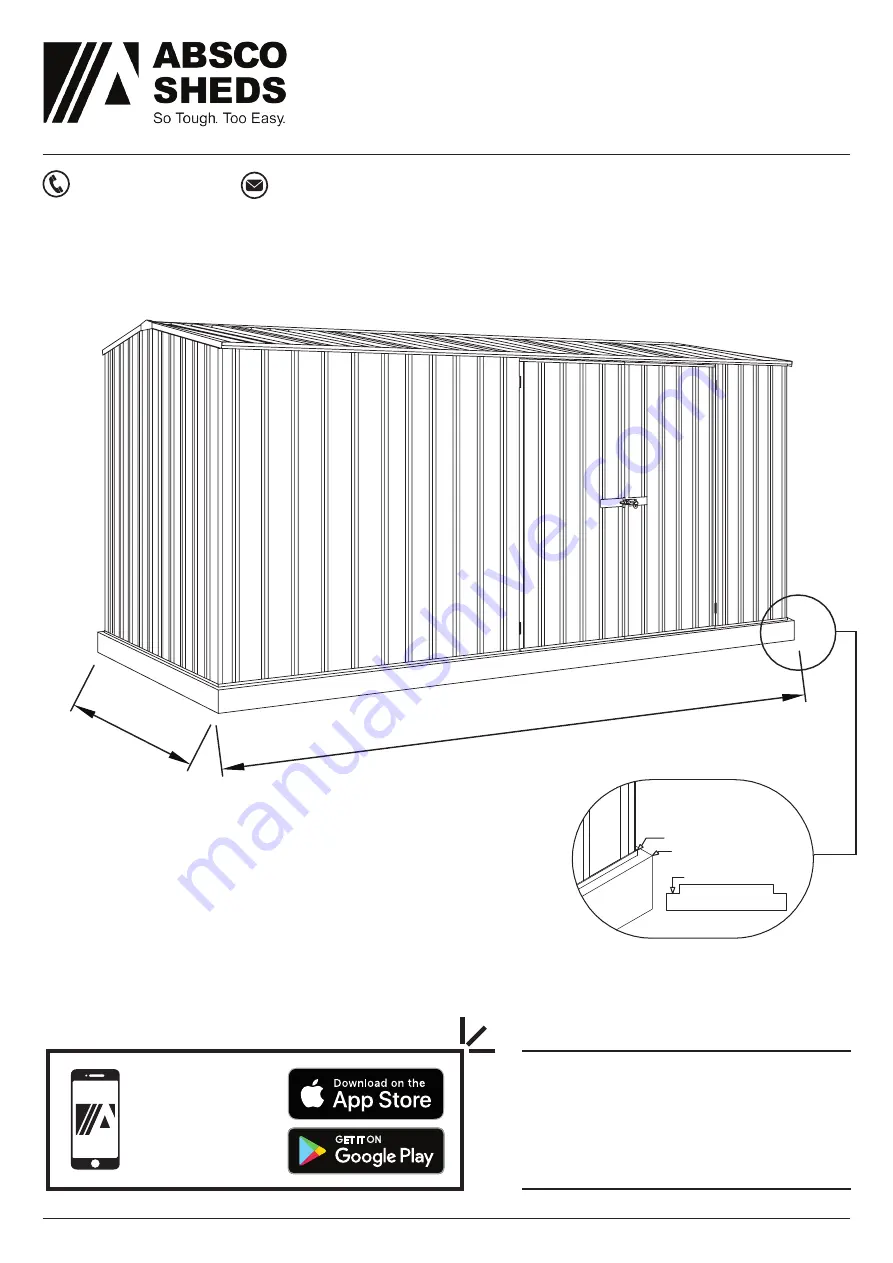

CONCRETE SLA

B

4580mm

3100m

m

When laying concrete slab, ensure there

is a rebated edge 25mm deep around

the perimeter. This will help water egress

from the base of the shed.

For construction in non-cyclonic areas

Wind rating: N2 as per AS4055-2012.

If you require a higher wind rating please contact

us: admin@absco.com.au or 1800 029 701

NOTE: This shed can be upgraded to wind

rating: C1 as per AS4055-2012 with the additional

purchase of a Cyclone Kit.

ABSCO INDUSTRIES

ASSEMBLY INSTRUCTION MANUAL

SHED MODEL: 23151GK

21-11-2017

CONCRETE SLAB

2360mm

1620mm

FRONT: 2.26m

SIDE: 1.52m

HEIGHT: 1.95m

We thank you for choosing an Australian made

shed. For further assistance please visit our detailed

instructional video library at

Http://www.abscosheds.com.au/watch-videos

At ABSCO Industries we are always looking to be

number ONE, so please let us know what you think

of our instructions. Feedback makes us better.

feedback@absco.com.au

CONCRETE

REBATED EDGE

BOTTOM CHANNEL

CONCRETE SLAB

75mm WIDE REBATE

100mm

WHEN LAYING YOUR CONCRETE

SLAB, ENSURE THERE IS A

REBATED EDGE 25mm DEEP

AROUND THE PERIMETER

THIS WILL HELP WATER EGRESS

FROM THE BASE OF THE SHED

Absco Industries

Premier Shed Model: 23151GK

PAGE 01