Summary of Contents for 1250

Page 1: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...

Page 2: ......

Page 3: ...Model 1250 Wheel Balancer...

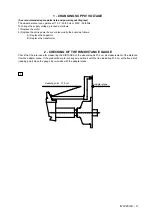

Page 5: ...M 0495 2 GB...

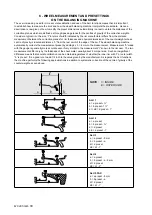

Page 9: ...M 0495 6 3 GB 5 POWER SUPPLY LAYOUT DIAGRAM 230 V connection...

Page 10: ...M 0495 7 4 GB 6 REPLACING THE POWER BOARD check voltage...

Page 14: ......

Page 15: ...Model 1450 Wheel Balancer...

Page 17: ...M 0492 2 GB...

Page 30: ......

Page 31: ...Model 1550 Wheel Balancer...

Page 33: ...M 0493 2 GB...

Page 40: ...M 0493 9 5 GB 6 POWER SUPPLY LAYOUT DIAGRAM...

Page 41: ...M 0493 10 6 GB 7 TO REPLACE POWER BOARD...

Page 46: ......

Page 47: ...Model 1650 Vibration Control Diagnostic System...

Page 49: ...M 0494 2 GB...

Page 55: ...M 0494 8 5 GB 7 POWER SUPPLY LAYOUT DIAGRAM...

Page 56: ...M 0494 9 6 GB 8 TO REPLACE POWER BOARD...

Page 62: ......

Page 63: ...Model 1850 Wheel Balancer...

Page 65: ...M 0496 GB 2...

Page 76: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...