Instructions

GB

5762H402 Ed.01

AKO-57624

3

5

5

7

6

2

4

0

2 R

EV

.0

0 2

0

1

9

AKO ELECTROMECÁNICA

, S.A.L.

Avda.

Roquetes, 30-38

08812

•

Sant Pere de Ribes.

Barcelona

•

Spain.

Tel.: +34 902 333 145

Fax: +34 938 934 054

www.ako.com

We

reserve the

right to

supply materials

that might

vary

slightly to

those

described in

our Technical

Sheets.

Updated information

is av

ailable on

our

website.

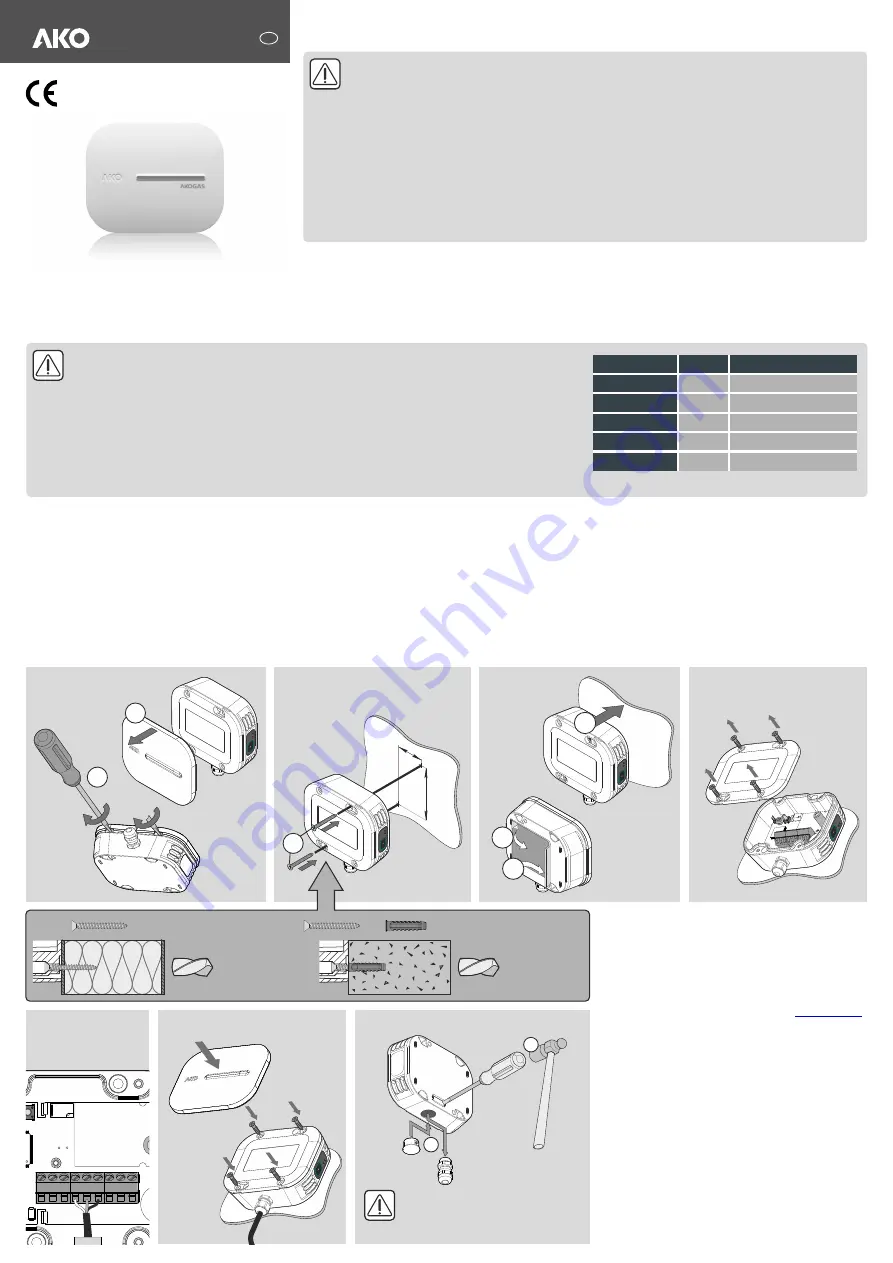

Installation

2

1

Option A

Fixed by screws

36 mm

70 mm

3

1

2

Optional rear

cable entry

3

.3

3

.1

3

.2

Option B

Fixed by an

adhesive

General warnings

-Using the unit without observing the manufacturer's instructions may alter the appliance's safety requirements.

- Detectors should be installed in a place protected from vibrations, water and corrosive gases, where the ambient

temperature does not exceed the value indicated in the technical data.

- Detectors supervise a point and not an area. If the gas leak does not reach the sensor, or the level of

concentration in that point does not reach the alarm values, no alarm will be activated. If perimeter

supervision is required, several sensors should be installed around that area.

Working conditions:

-Keep the detector work environment free of chemical agents (such as solvent, paints, alcohol, acetone, silicone, etc.), and

free of engine fumes or gases from fermentations (bread, pizza) or ripening (breathing) of fruits.

-The detector should generally be installed in an area of potential concentration/accumulation of gas, in low positions (due

to the greater relative density, in relation to air, of the gases subject to detection).

Connect

following the

diagrams

x2

Ø 2,8 mm

x2

+

Ø 5 mm

Carefully perforate the rear entry so as not

to damage the electronic board.

This option involves changing from

IP68 to IP40.

Warning

The

AKO-57624

refrigerant gas detector may only be used in locations that have not been classified with risk of

explosion.

The detector is set at a value lower than 25% of the LEL (Lower explosion limit) of the refrigerant (see table). In the

event that the concentration of the refrigerant leak reaches the setting value, the detector activates an alarm and must

activate a forced ventilation system (*).

(*) The forced ventilation system must be suitably proportioned to ensure that the concentration of refrigerant in the event

of a leak is below the LEL.

Reference regulations: EN 378

Applicable local regulations: Compliance must be ensured

Refrigerant

LEL (%)

Detector settings (%)

R-1234yf

6.2

< 1.5

R-454C

7.9

< 2

R-454A

8.5

< 2.1

R-455A

11.9

< 2.9

R-32

14.5

< 3.6

Technical specifications

Power supply.........................................................................................................12-30 Vdc

Consumption Typical ..............................................................................................75 mA

Maximum .......................................................................................150 mA

Alarm relay ...................................................................................SPDT 30 Vdc, 2A, cos

j

=1

Working ambient temperature .............................................................................-20 to 50 ºC

Storage ambient temperature ..............................................................................-20 to 60 ºC

Range of moisture permitted ............................................0 - 95 % RH (Without condensation)

Protection degree ..........................................................................................................IP68

Dimensions ...................................................................107 mm (W) x 85 mm (H) x 39 mm (D)

Complies with the EN 14624 standard.