AKO-575744NR

5757H412 Ed.01

AKO ELECTROMECÁNICA , S.A.L.

Avda. Roquetes, 30-38

08812

•

Sant Pere de Ribes.

Barcelona

•

Spain.

Tel.: +34 902 333 145

Fax: +34 938 934 054

www.ako.com

GB

Start-up

3

5

5

7

5

7

4

1

2 R

ev 0

0 2

0

2

1

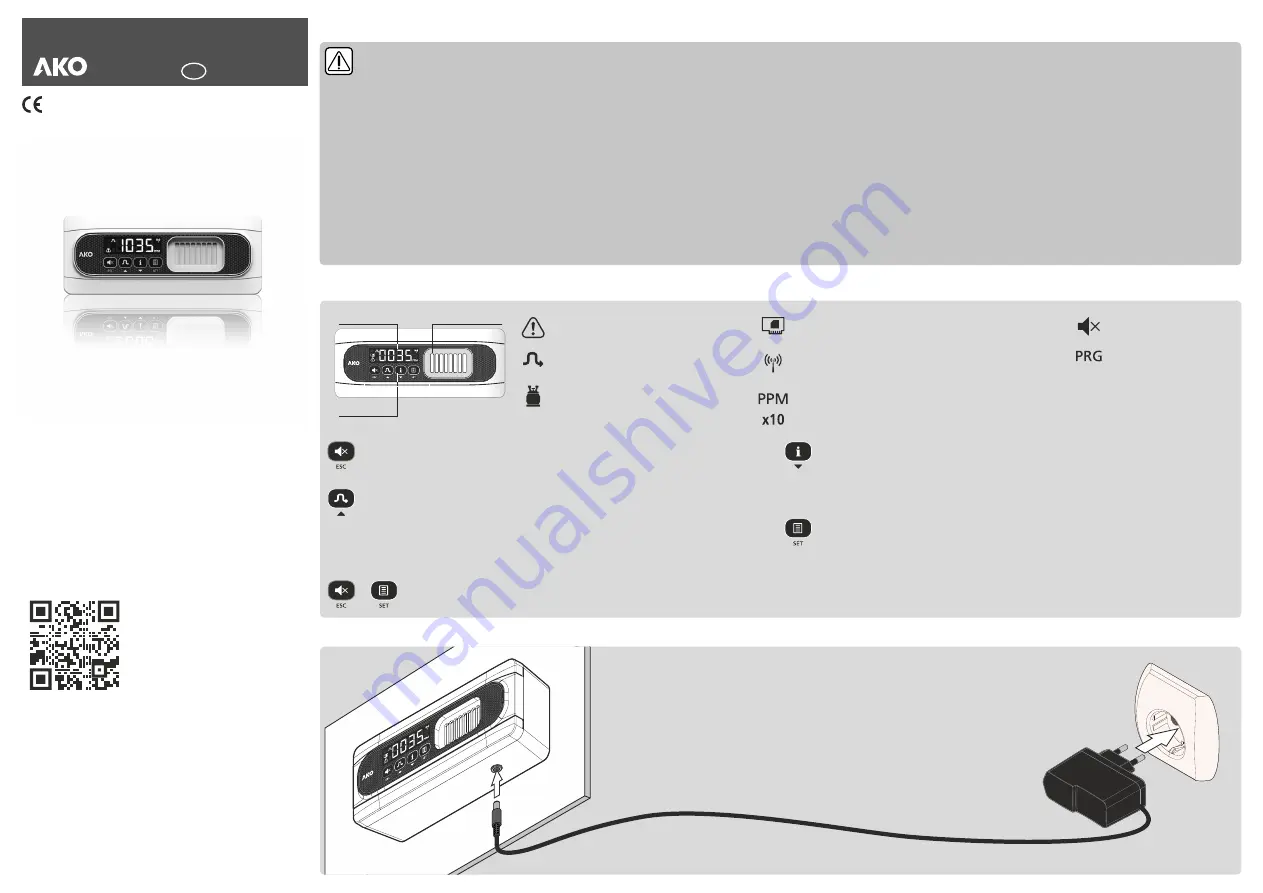

INSTALLATION

Follow the instructions included in the installation template.

CO gas transmitter with

2

NBIoT communication

Quick guide

akonet.cloud

We reserve the right to supply materials that might vary slightly to those described in

our Technical Sheets. Updated information is available on our website.

Warning

-Transmitters / detectors should be installed in a place protected from vibrations, water and corrosive gases, where the ambient temperature does not exceed the value indicated in the technical data.

-The transmitters / detectors are not suitable for areas classified as potentially explosive.

-Transmitters/detectors supervise a point and not an area. If the gas leak does not reach the sensor, or the level of concentration in that point does not reach the foreseen values

according to the type of gas no alarm will be activated. If perimeter supervision is required, several sensors should be installed around that area.

-Avoid installing the device on metal walls or near devices that may produce radio emissions.

-This device must be installed in a location where a minimum distance of 20 cm to the human body can be guaranteed, in order to ensure compliance with standards on human exposure to electromagnetic fields.

Working conditions:

-Avoid handling refrigerant gases near the sensor. If this is unavoidable, use Set Hold or Maintenance mode. Do not paint the sensor or place it near solvents or paints. Exposure to acetone vapours may

generate false alarms.

-The sensor should be installed away from: -Smoke outlets located in confined spaces or from engines, generators or motorised machinery (fork-lift trucks, etc.).

-Particularly damp areas or areas with strong ventilation.

-The detector should usually be installed in an area where gas may concentrate, near places where gas leaks could start

-CO is heavier than air. Therefore, it always concentrates in the lowest part of the refrigerated room or space. Please take this into consideration when choosing the installation site. It is advisable to leave a

2

distance of around 50 cm free.

Descrip i n

t o

Gas sensor

Keyboard

Display

Constant:

NBIoT module in operation

Flashing:

Malfunction in NBIoT module

Constant:

Connected to the NBIoT network (Narrow band)

Switched off:

NOT

connected to the NBIoT network or expired license.

+

Forces data transfer to the cloud via NBIoT connectivity.

If the gas Pre-Alarm or Alarm sounds, pressing once will mute the alarm tone (See parameter

b03

).

In the programming menu, it exits the parameter without saving changes, returns to previous

level or exits programming.

Pressing for 3 seconds activates or deactivates Set Hold mode.

Pressing for 6 seconds activates or deactivates maintenance mode.

In the programming menu it allows scrolling around the different levels, or during the setting of

a parameter, changing its value.

Fixed:

Gas pre-alarm activated.

Flashing:

Gas alarm activated.

Fixed:

Set Hold mode activated

Flashing:

Maintenance mode activated

The display shows the type of gas detected.

The display shows the current gas concentration in ppm (parts per million).

The value displayed should be multiplied by 10.

Gas alarm on mute

Unit in programming mode.

Pressing once (< 1 second) will show the type of gas detected, the date and time in

sequential order.

Pressing for 3 seconds displays the Pre-Alarm and Alarm levels that have been configured.

In the programming menu it allows scrolling around the different levels, or during the

setting of a parameter, changing its value.

Pressing for 3 seconds accesses the configuration of alarm and pre-alarm levels.

Pressing it for 6 seconds accesses the advanced programming menu.

In the programming menu, it accesses the level shown on the display or, during the

setting of a parameter, accepts the new value.

All manuals and user guides at all-guides.com