Description

With covers manufactured from high quality impact resistant and UV stabilised polypropylene and a positive latching mechanism that

automatically locks hose at the desired length, the new S Series of plastic hose reels from Alemlube will provide you with a reliable

& cost effective means of storing and retrieving hose assemblies in your workshop or garden. The reels can be floor, ceiling or wall

mounted & the detachable mounting bracket facilitates ease of reel mounting & storage.

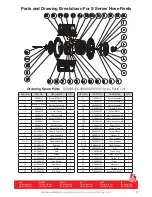

Specifications

Operation

1 Check your S Series reel for correct operation by slowly pulling out the hose.

A clicking noise will be heard every half revolution of the drum.

2 Latching mode switch, when your S Series reel is in free run state, pull out

the hose and allow it to retract after hearing the first, second or third click.

3 To unlatch the reel, slowly pull out the hose until the clicking noise stops, and

then let the hose retract unitl the hose stop rests against the hose guide.

4 NOTE: To avoid damage to your S Series reel, always hold onto the hose while it is rewinding. Periodically check the hose

condition for wear or damage and check the swivel fitting for leakage. Replace any worn, damaged or leaking parts.

Warning

1 Make sure incoming line pressure does not exceed the rated operating pressure for your model hose reel.

2 Use proper eye protection when assembling and using the hose reel.

3 Use soap and water when checking for leaks.

4 Keep children away from the work area.

Installation Of Reel

1 For overhead ceiling mounting: install reel at most,

3m above the floor.

2 You will need to purchase appropriate hardware for the

mounting of your new reel.

3 The reel base has four 7mm (11/16”) drilled holes for

mounting on a suitable flat surface. Figure 2 is a

template showing the correct location of the 4 mounting

holes in the base.

4 Using the three holes in the base, mount the reel in the

desired location. Be sure to use appropriate hardware

and to tighten the reel securely to the mounting location.

5 Apply Teflon tape or pipe sealant to the outlet fitting on the

hose & then attach to desired tool or nozzle. Check

connection for any leakage & check the reel for correct

operation. See operation section. If hose stop adjustment is

required, pull hose from reel and allow the reel to latch at the

desired length. Loosen hose stop bolts and slide hose stop to

a position close to the hose guide. Tighten hose stop bolts

and unlatch the reel.

Uses/Pressure

Air. Max. operating pressure: Air Reels: 290psi Water Reel: 145psi

Hose Lengths

SA300N – 18m x 10mm ID hose. SA400N – 15m x 12mm ID hose.

Materials

Plastic covers, steel spring & Buna “N” seals

Pressure

SA300N, SA400N – 300 psi (20 bar)

Weight/Dimensions

10kg / 490mm (L) x 448mm (H) x 228mm (W)

Inlet/Outlet

SA300N – 3/8

"

BSPT(m) / 3/8

"

BSPT(m)

SA400N – 1/2

"

BSPT(m) / 1/2

"

BSPT(m)

Working Temp

-10°C

~

60°C

Visit our website at

www.alemlube.com.au

or

www.alemlube.co.nz

S Series Hose Reels

SA300N

SA400N

OWNER’S TECHNICAL MANUAL

NSW

TEL: (02) 9939 0711

FAX: (02) 9939 0411

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9209 3066

FAX: (08) 9209 3933

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (09) 447 1007

FAX: (09) 447 1008