RENEWAL PARTS

I

FULL VOLTAGE

REVERSING STARTERS - SIZE 4

OPERATION-

Bulletin 505 starters are most commonly used for

full voltage starting and reversing of polyphase squirrel cage

motors.

Bulletin 505 starters consist essentially of a “forward” and a

“reverse” contactor mounted to a common base. These

contactors are electrically and mechanically interlocked to

guard against both contactors closing at the same time.

Starters are equipped with Bulletin 592 block type manual

reset overload relays.

OPERATING ENVIRONMENT

- Starters should always be

maintained in a clean and dry condition for dependable

operation. Choice of the proper NEMA enclosure type for the

application is very important.

PREVENTIVE MAINTENANCE

- For recommended preventive

maintenance instructions refer to Publication GI-5.0 or the

Handy Catalog.

REPAIRS

- Contactors can be disassembled as depicted in the

“exploded” illustration on Page

procedures and techniques are suggested to aid in the

sequential disassembly and reassembly of a contactor.

WARNING

- Before part replacements are attempted the

POWER SOURCE MUST BE DISCONNECTED.

NOTE

- If parts are removed from both contactors, keep them

separateand replacethem in theiroriginal positions, if reused, to

avoid mismatched wear patterns.

DISASSEMBLY [Partial]

- The following instructions apply to

both the left hand and right hand contactors.

1. Remove all control wires from theoperating coil (Item 7) and

tie point terminal (Item 5). Tag removed wires.

2. Loosen two captive screws and lift off thecontact block cover

(Item 1).

3. Loosen four captive screws from the coil cover (Item 4). The

tie point terminal is now free to be removed, if it is to be

replaced.

4. With the coil cover screws loosened the auxiliary contact

block(s) (Item 6) can be removed and the coil cover lifted off.

5. Lift out the movable contact support and armature assembly

(Item 2), the yoke (Item 8) and theoperatingcoil (Item 7) as a

unit. The yoke and the operating coil can now be lifted up and

out of the movable contact support assembly.

REPLACING CONTACTS-With

steps 1-5 under DISASSEMBLY

completed inspect the contact surfaces for evidence of wear.

When severe contact wear is evidenced it is recommended that

all contacts be replaced. Replacing all contacts will guard

against uneven and unequal contact closings. Order the

required number of single pole contact sets from the part listings

Movable Contacts

- The following instructions describe the

replacement of movable contacts.

1. Remove the movable contact (Item 9) by depressing the

contact spring (Item 10) and pushing the contactouttoeither

side. The contact spring will fall free or can be lifted out.

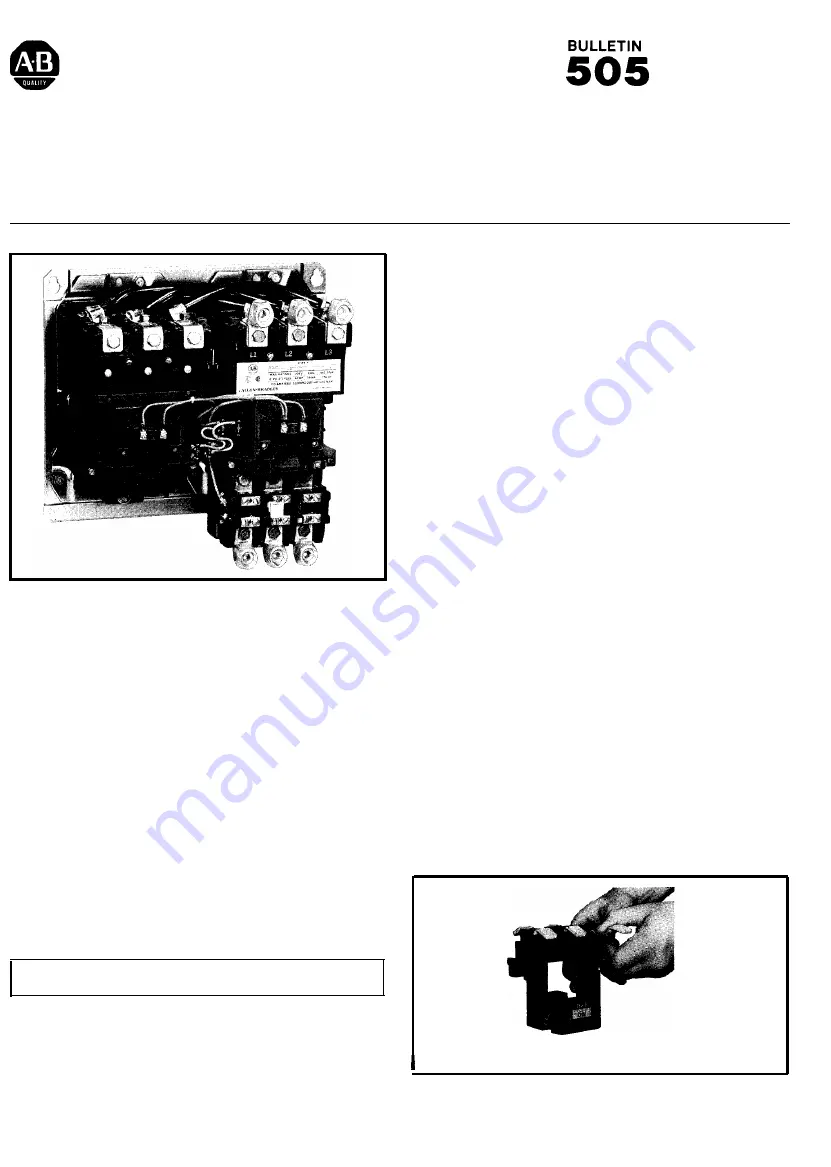

2. Hold the replacement spring and contact in one hand as

shown in Figure 1.

3. Butt the contact spring against the side of the “seating

projection” on the movable contact support assembly. Slip

the movable contact through the opening on the movable

contact support assembly. Rock the spring into position over

the seating projection on the movable contact support and

the movable contact.

4. Check to determine that the spring is holding the contact

centered

Figure 1

Publication 505-6.3--November, 1981