Installation Instructions

Original Instructions

Prosafe Electronic Time Delay Unit

Catalog Numbers 440T-MSTUE

x

, 440T-MDTUE

x

Summary of Changes

This publication contains new and updated information regarding the

Prosafe® Electronic Time Delay Units as indicated in the following table.

Installation must be in accordance with the following steps and stated

specifications and implemented by suitably competent personnel. This

device is intended to be part of the safety-related control system.

Before installation, perform a risk assessment to determine whether the

specifications of this device are suitable for all foreseeable operational

and environmental characteristics of the machine to which it is to be

fitted.

At regular intervals during the life of the unit, check whether these

characteristics foreseen remain valid. Inspect this device for evidence of

accelerated wear, material degradation, or tampering. If necessary,

replace the device. The manufacturer cannot accept responsibility for a

failure of this device if the procedures are not implemented or if it is

used outside the recommended specifications.

Adherence to the recommended maintenance instructions forms part of

the warranty.

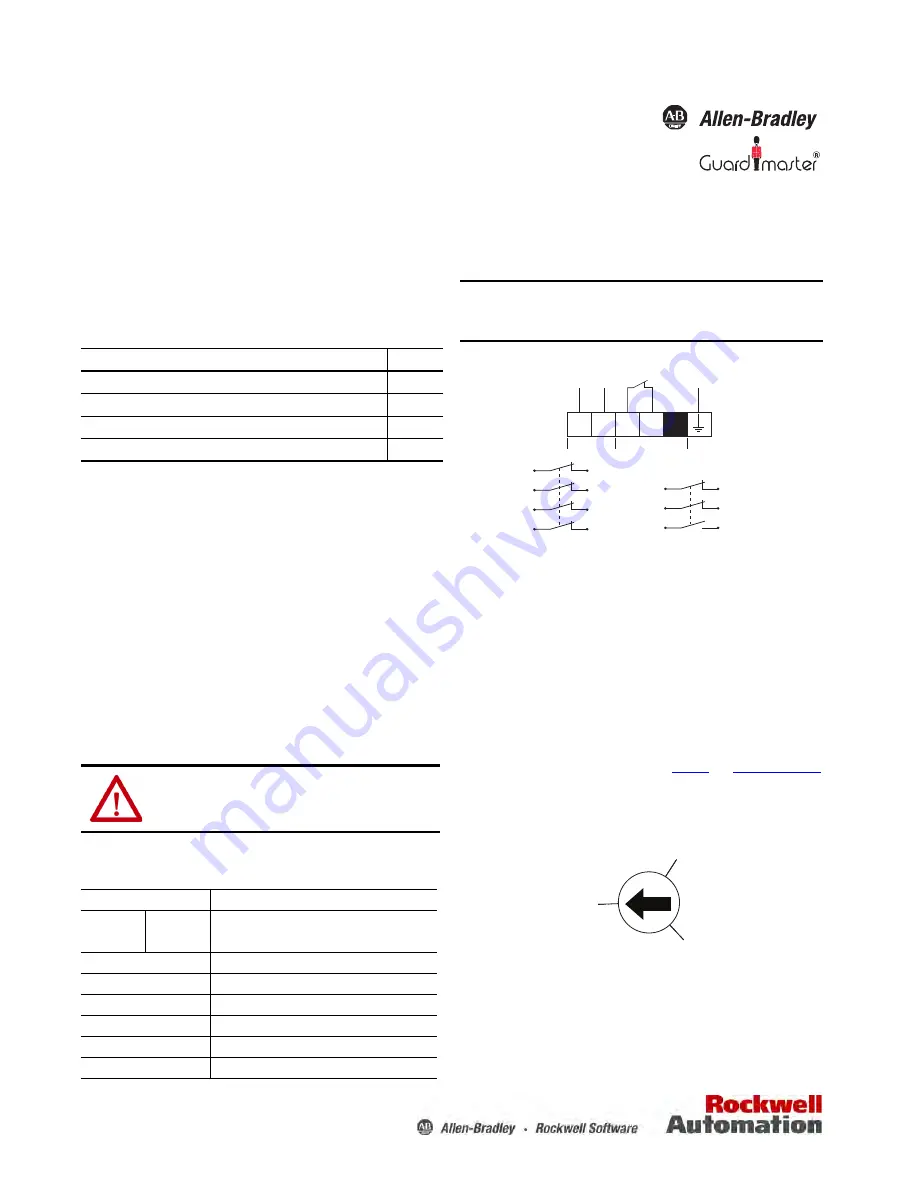

Figure 1 - Wiring Diagram (Shown with Power On)

EMD Safety Relay

The EMD safety relay has two switches. The combination of the switch

settings determines the functionality and the duration. During

configuration, the Time switch determines the duration of the range

switch.

To configure, power the unit OFF. Set the range switch to zero and the

time switch to either 1 (for short range timing) or 10 (for long range

timing). Apply power and adjust the time and range switches, as

necessary. Due to intended operation of this unit, only on-delay range

settings 5, 6, and 7 can be used. After adjusting the switches, cycle the

power to the unit to store the settings. See

Table 3

and

Table 4 on page 3

for Range and Time Switch Adjustments.

SI Safety Relay

The SI safety relay is set to AM (automatic reset) at the factory. Verify

that it is still set to AM. Do not change this setting.

Topic

Page

Added EMD Safety Relay section

1

Replaced Logic Setting section with SI Safety Relay

1

Adjustments to dimensional drawings

2

New Time and Range Setting tables

3

WARNING:

Do not defeat, tamper, remove, or bypass this unit.

Severe injury to personnel could result.

Table 1 - General Specifications

Attribute

440T-MSTUEx, 440T-MDTUEx

Safety contacts

Isolator on

(STUE and

DTUE)

3 N.O. Safety (40 A) + 1 N.O. (20 A)

2 N.O. Safety (20 A) + 1 N.C. (20 A)

Solenoid monitor switch

1 N.C. Safety (10 A)

Input voltage

24V DC (6.5 W)

Mechanical life

100,000 (typical)

Shear force to key, maximum

15.1 kN (3398 lbs)

Torque to key, maximum

14 N•m (10.12 lb•f)

Operating temperature

-10…+40 °C (14…104 °F)

IMPORTANT

The safety contacts of these products are described as normally

closed (N.C.). For example, with the guard closed and the

actuator in place (where relevant), the machine is able to start.

Solenoid Monitor

Signal Input

+

-

1

3

5

13

2 (40A)

4 (40A)

6 (40A)

14 (20A)

1

3

7

2 (20 A)

4 (20 A)

8 (20 A)

Safety

Safety

Safety

Safety

STUE 10, 20, 30, DTUE 10, 20, 30

STUE 11, 22, 33, DTUE 11, 22, 33

RESET

0

MM

AM