p r i n t e d

i n

u

.

s

.

a

.

W164 N9221 Water Street • P.O. Box 450

Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE:

262.251.3800 • 800.558.8744

U.S.A. / CANADA

FAX:

262.251.7067 • 800.329.8744

U.S.A. ONLY

www.alto-shaam.com

Consult instructions

for operation and use.

Hot Food Holding

Drop-In Wells

Electric

500-HWI/D4

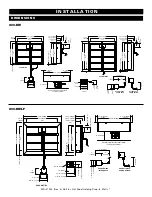

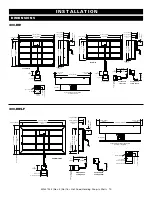

• InstallatIon

• operatIon

• MaIntenance

Models:

100-HW/D4/D6/D443/D643

100-HWlF/D4/D6

200-HW/D4/D6/D443/D643

200-HWlF/D4/D6

200-HWI/D4/D6/D443/D643

200-HWIs/D6

200-HWIlF/D4/D6

300-HW/D4/D6/D443/D643

300-HWlF/D4/D6

300-HWI/D4/D6/D443/D643

300-HWIs/D6

300-HWIlF/D4/D6

400-HW/D4/D6

400-HWlF/D4/D6

400-HWI/D4/D6

400-HWIlF/D4/D6

500-HW/D4/D6

500-HWlF/D4/D6

500-HWI/D4/D6

500-HWIlF/D4/D6

400-HW/D4

300-HWI/D6

100-HW/D6

MN-37234 (

rev

. 3) • 06/16

200-HWIS/D6