Summary of Contents for PRO-18A

Page 1: ...FOUR POST LIFT Model PRO 18A ...

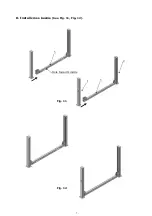

Page 9: ... 7 D Install cross beams See Fig 11 Fig 12 Fig 11 Fig 12 2 Hole towards inside 1 3 3 ...

Page 23: ... 21 P Install spring and safety cover of cross beam See Fig 32 Fig 32 3 3 3 8 40 3 2 ...

Page 26: ... 24 CROSS BEAM CYLINDERS Fig 35 Fig 36 3 ...

Page 27: ... 25 MANUAL POWER UNIT Fig 37 Manual 220V 60Hz 1PH ...

Page 34: ... 32 ...

Page 37: ... 35 ...