330118

lliJ-------I

N_s_r_R_u_c_r_1o_N_S_H_E�ET

COMPANY

Instruction for Installation, Operation and Maintenance

of

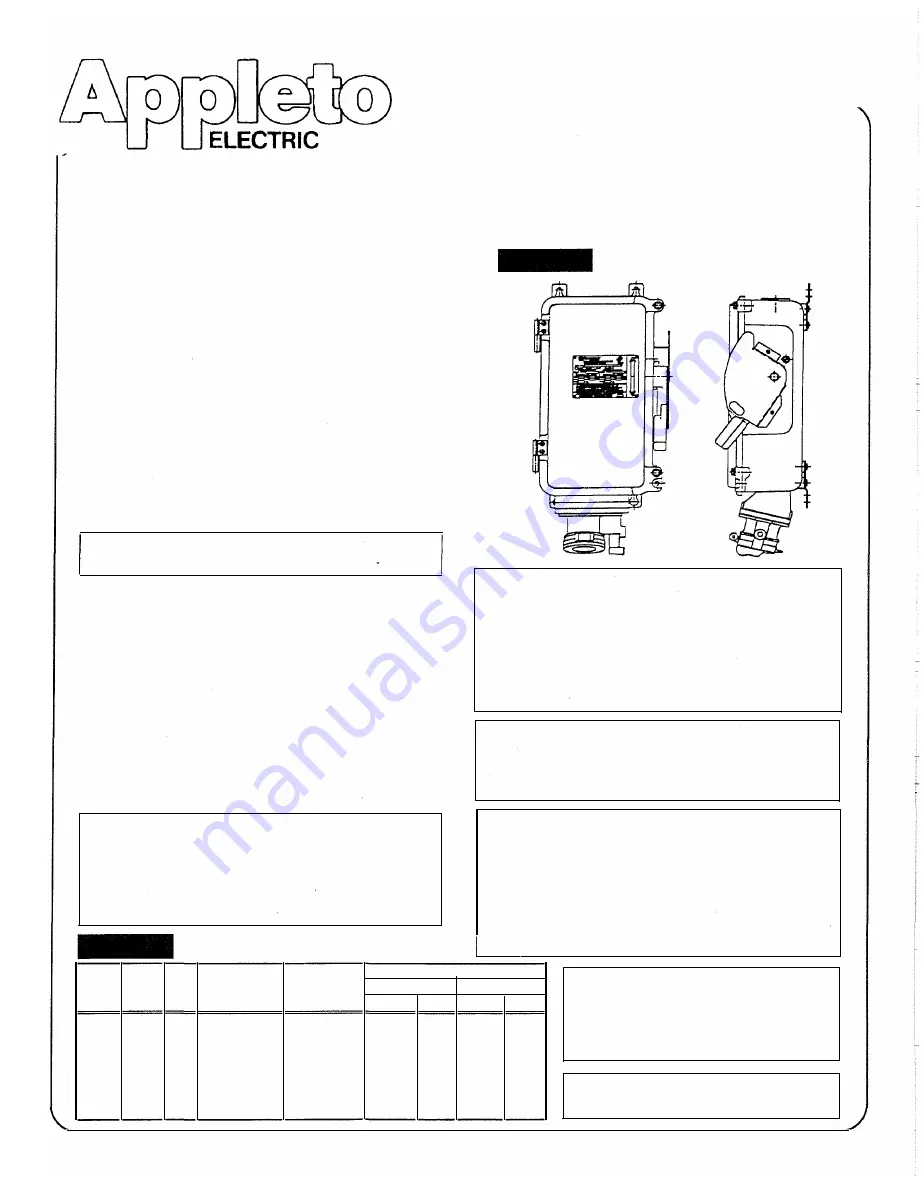

11

WSR

11

Interlocked Receptacles: 30, 60 & 100 Ampere

"WSR" SERIES:

Heavy duty single throw safety switch with interlocked

Appleton Powertite

®

compatible receptacle .

COMPLIANCES:

UL. Listed, File No. 145917

UL498 - Attachment Plugs and Receptacles

UL98 - Enclosed and Dead-Front Switches

UL50 •· Enclosures for Electrical Equipment

NEC wire bending space, Table 373-6(b).

ELECTRICAL RATINGS:

Maximum Voltage: 600VAC at 60 Hz, 250 VDC 30, 60 or 100

Amperes, depending on current rating of product

( See product nameplate for details )

Read instructions carefully and with full understanding for

safe installation and operation..

STANDARD FEATURES:

• Epoxy coated finish on receptacle and disconnect

switch housing.

• Current carrying parts in housing are all plated copper

• Lugs ·· front removable, standard mechanical lugs on

incoming line .. L.ay-•in ground lug.

• Screw cover assembly provided for 60 & 100 Ampere

units which can be used on receptacle housing,

instead of flip cover assembly to meet certain environ

mental conditions ..

OPTIONS:

• Electrical Interlocks -1 N.O., 1 N. C. or 2 NO, 2 N .. C.

MODIFICATION WARNING

Do not modify these devices in anyway .. Replace any missing

or broken parts with the proper replacement parts from

Appleton Electric. Modification of these devices or substitution

of parts with non-standard parts may result in serious/fatal

personal injury from electrocution.

TABLE A

HORSEPOWER RATING:

FIGURE A

Except as expressly provided by Appleton Electric

Company (Appleton) in writing, Appleton products are

intended for ultimate purchase by industrial users and for

operation by persons trained and experienced in the use

and maintenance of this equipment and not for consumers

or consumer use .. Appleton warranties do not extend to, and

no reseller is authorized to extend Appleton's warranties to,

any consumer.

ELECTRICAL WARNING

Electrical power must be turned

OFF

before and during

installation and maintenance.

Failure to do so m ay result

in serious

I

fatal injuries due to electrocution.

DAMAGE WARNING

If any parts of the "WSR" unit or the mating plug appear to be

missing, broken or show signs of damage:

DISCONTINUE USE IMMEDIATELY

This condition could cause serious/fatal personal injury due to

electrocution and/or equipment damage. Repair replacement

part(s) before continuing service with the proper replace

ment part(s) before continuing service

HORSEPOWER RATINGS

WARNING

DC

AC

CA1ALOG

SWITCH

AC

DC

VOLTS VOLTS AMP

NUMBERS

TYPE

STAND. MAX. STAND. MAX.

250 600

30

WSR3352

FUSED

7.5

20

5

---

250 600

30

WSR33542

NON-FUSED

......

20

---

5

250 600

60

WSR6352

FUSED

15

50

10

-·--

250 600

60

WSR63542

NON-FUSED

---

50

--·-

10

250 600 100

WSR10352

FUSED

30

75

20

---

250 600 100

WSR103542

NON-FUSED

-·--

75

.......

20

The

"WSR"

receptacles are designed and

tested for use with copper conductors only.

DO NOT

use aluminum wiring,as dangerous

overheating and fire may result.

WARNING

Not suitable for use as service equipment.

Rev. A 3/29/95

Page 1