These instructions describe the steps to install a standard Yarra Horizon

lock for general application. For other Yarra Horizon variations and non-

standard applications, additional instructions may be required.

Read through all instruction steps before beginning installation. When

replacing an older lock, modify the existing installation holes in the door

stile and jamb if necessary.

IMPORTANT: If installing an EGRESS Yarra Horizon D-Pull, test

the lock after installation to ensure correct operation. The interior

lever on the EGRESS D-Pull must allow unlocking at all times. Test

by locking the exterior by key, then rotate the interior lever. The

interior lever must be free to retract the beaks.

E TH

L

C

IS

Y

P

C

A

E

C

R

K

E

A

S

G

A

IN

E

G

L P

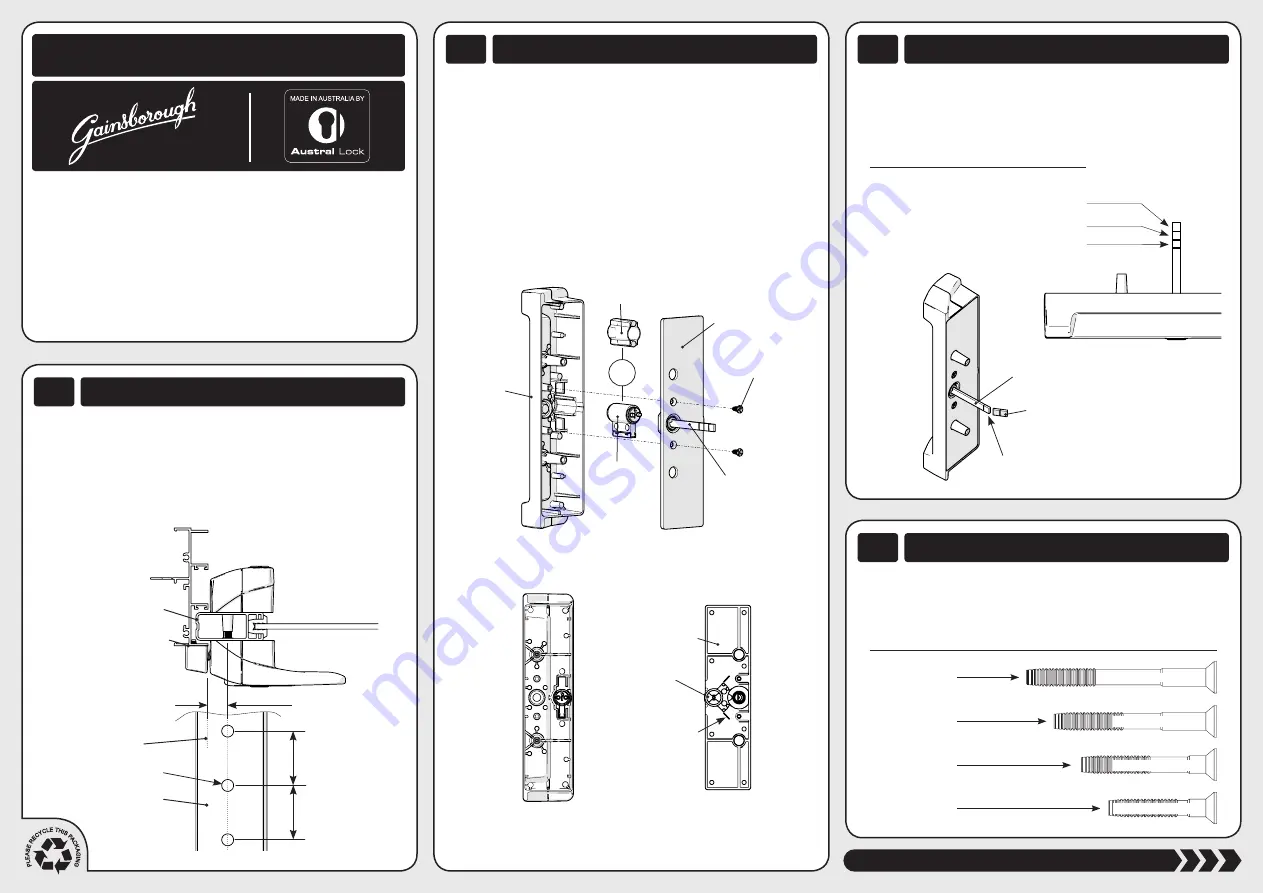

1.

Door preparation

• For optimal installation, ensure the door is rolling smoothly and

closing parallel into the jamb by lubricating and adjusting the rollers.

Close the door and lightly mark the door stile at the edge of the

overlapping jamb.

• Prepare three 9.0mm holes in the door stile as dimensioned below in

Figure A. Ensure the holes are straight and free from burr.

2.

Cylinder installation

• To remove a Cylinder Plug and install a Keyed Cylinder in the

Exterior Assembly, remove the Base Plate Screw and lift off the

Base Plate Assembly. Remove and discard the Cylinder Plug.

• Install the Keyed Cylinder into the Exterior Pull by matching the

orientation shown in Figures B and C.

• Hold the Base Plate Assembly by the Spindle. Using the Alignment

Markings on the Base Plate as a guide, ensure the Cylinder Gear is

orientated as shown in Figure D.

• Place the Base Plate Assembly onto the Exterior Pull. If the Base

Plate does not sit flush with the rear of the Exterior Pull, rotate the

Spindle until it drops into place. Replace the Base Plate Screw.

3.

Cylinder installation CONT.

4.

Select fixing screws

Use the table below with Figure E to decide the correct length of the

Spindle. Add the packer thickness to the door thickness in table if

using packers. If necessary, use pliers or a vice to carefully break off

the required number of pre-notched portions of the Spindle to suit the

door thickness.

• Several pairs of Fixing Screws are provided to suit different door

thicknesses. Use the table below to identify which are the correct

length Fixing Screws. Add the packer thickness to the door

thickness in table if using packers.

PLEASE TURN PAGE FOR INSTALLATION STEPS 5 - 8

1 3/4” Fixing Screw

1 1/2” Fixing Screw

1” Fixing Screw

1 1/4” Fixing Screw

46.4 to 40.2mm

40.1 to 33.9mm

33.8 to 27.6mm

27.5 to 21.3mm

Door thickness

Door thickness

Screw selection

Spindle preparation

(optional)

Break off ‘0’ portions

Break off ‘1’ portion

Break off ‘2’ portions

Break off ‘3’ portions

46.4 to 40.2mm

40.1 to 33.9mm

33.8 to 27.6mm

27.5 to 21.3mm

(optional)

YARRA HORIZON STANDARD OUTER PULL

Mark and

measure

from this

edge

14.0 mm

41.0 mm

41.0 mm

Door Stile

Door Stile

Mark

Ø 9.0 mm

Door Jamb

Interior

Exterior

Figure A

Figure B: Exterior Pull Assembly

Exterior

Pull

Spindle

Base plate

screw

Base plate

assembly

Keyed

Cylinder

Cylinder

Plug

OR

Cylinder

Gear

Alignment

Markings

Base Plate

assembly

Figure C: Installing a

keyed cylinder

Figure D: Cylinder

Gear Orientation

Figure E

Discard

Spindle

Notch