HGM300/RDM800 PREVENTATIVE MAINTENANCE AND TECHNICAL SUPPORT

SECTION 1

– HGM300 CPU reset, RDM800 CPU reset, WARM UP notes and HGM300 Self

Test

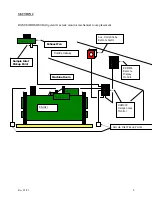

SECTION 2

- HGM300/RDM800 Mechanical Room layout

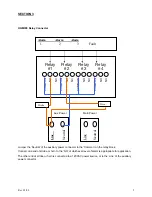

SECTION 3

– HGM300 Relay Connector

SECTION 4

– Flow check procedure

SECTION 5

– Clipping fault adjustment

SECTION 6

– Dual loop 4-20 mA dc scrolling output

SECTION 7

– HGM300 voltage check Dual loop 4-20 mA dc scrolling output

SECTION 8

– Alarm silencing

SECTION 9

- NDIR Sensor

SECTION 10

– Gas verification test procedures

A-

Procedure with RDM800

B-

Procedure with PC software

SECTION 11

– Password protection

SECTION 12

– Whom to call - Warranty

Rev 3/2/09

1