1

A. 11/16 SB 1145

2016_1

1_4-8:10

CF15

CF10

CF30

CF10

CF15

CF30

Ratio

1:1

1:1

1:1

Maximum free flow

10 gal/min (38 l/min)

13.21 gal/min (50 l/min)

22.7 gal/min (100 l/min)

Delivery per stroke

2.37 oz (0,07 l)

3.38 oz (0,1 l)

32 oz (0,25 l)

Air pressure operating

range

43.51 to 100 psi (3 a 7 bar)

43.5 psi - 100 psi (3 a 7 bar)

43.5 psi - 100 psi (3 a 7 bar)

Solid in suspension max

size

0.12 in (3 mm)

0.12 in (3 mm)

0.16 in (4 mm)

Maximum suction head

13.2 ft (4 m) dry

26.25 ft (8 m) wet

19.69 ft (6 m) dry

26.25 ft (8 m) wet

14.76 ft (4,5 m) dry

22.97 ft (7 m) wet

Weight

4.85 lb (2, 2 kg)

7.72 lb (3,5 kg) metallic

6.17 lb (2,8 kg) plastic

15.87 lb (7,2 kg) metallic

14.33 lb (6,5 kg) plastic

Fluid inlet (single inlet)

1/2" NPT (F)

1/2” NPT (F) and fl ange

1/2” BSP (F) and fl ange-DEF

1” NPT (F) and fl ange

1” BSP (F) and fl ange-DEF

Fluid inlet (double inlet)

2 x 3/8" NPT (F)

2 x 3/8" NPT (F)

_

Fluid outlet

1/2" NPT (F)

1/2” NPT (F) and fl ange

1/2” BSP (F) and fl ange-DEF

1” NPT (F) and fl ange

1” BSP (F) and fl ange-DEF

Air inlet

3/8" NPSM (F)

3/8" NPSM (F)

3/8" NPSM (F)

Wetted materials

See model specifi cations

See model specifi cations

See model specifi cations

Noise level

80 db

80 db

80 db

Temperature range (see

material temperature

range on page 2)

0 - 158 ºF (0 - 70 ºC)

0 - 158 ºF (0 - 70 ºC)

0 - 158 ºF (0 - 70º C)

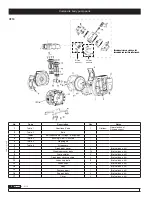

1/2" DOUBLE DIAPHRAGM PUMP CF10 (10 gal/min)

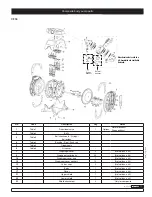

1/2" DOUBLE DIAPHRAGM PUMP CF15 (13.21 gal/min)

1" DOUBLE DIAPHRAGM PUMP CF30 (22.7 gal/min)

Operation and maintenance

manual

CF10

1120-029

CF15

1120-025

1120-027

1120-023

1120-028

CF30

1120-024

1120-026

1120-031

Technical data

1

Warnings and cautions

2

Description 2

Capacity curves

3

Dimensions 4

Installation 5

Operating instructions

6

Exploded views:

CF10

7

CF15 Polypropylene

8

CF15 Metallic

9

CF30 10

Repair kits / Wetted parts 11

Troubleshooting 12

Maintenance guide

14

Technical data

* (oz,ft,gal/min) all in EEUU units

Product customization

CODES: