NOTE:

Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified person-

nel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code (NFGC) NFPA No.

54-1992/ANSI Z223.1-1992. In Canada, refer to the current

edition of the National Standard of Canada CAN/CGA-B149.1-

and .2-M91 Natural Gas and Propane Installation Codes (NSC-

NGPIC). Wear safety glasses and work gloves. Have fire extin-

guisher available during start-up and adjustment procedures and

service calls.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal word DANGER, WARNING, or CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage. NOTE is used to highlight sugges-

tions that will result in enhanced installation, reliability, or

operation.

WARNING:

Never store anything on, near, or in contact

with the furnace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds, plastic or plastic containers, gasoline,

kerosene, cigarette lighter fluid, dry cleaning fluids, or

other volatile fluids.

3. Paint thinners and other painting compounds, paper

bags or other paper products.

Failure to follow this warning can cause corrosion of the

heat exchanger, fire, personal injury, or death.

WARNING:

The ability to properly perform mainte-

nance on this equipment requires certain expertise, me-

chanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance

on this equipment other than those procedures recom-

mended in the User’s Manual. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN POSSIBLE

DAMAGE TO THIS EQUIPMENT, SERIOUS PER-

SONAL INJURY, OR DEATH.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip-

ment failure, it is essential that maintenance be performed annually

on this equipment. Consult your local dealer for maintenance and

the availability of a maintenance contract.

WARNING:

Turn OFF the gas and electrical supplies to

the unit before performing any maintenance or service.

Follow the operating instructions on the label attached to

the furnace. Failure to follow this warning could result in

personal injury or death.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month, or as

required.

2. Check blower motor and wheel for cleanliness and lubrica-

tion each heating and cooling season. Clean and lubricate as

necessary. (See Section 2.)

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage. Clean as necessary.

5. Check for blockages of combustion-air and vent pipes.

CAUTION:

As with any mechanical equipment, per-

sonal injury could result from sharp metal edges, etc. Be

careful when removing parts.

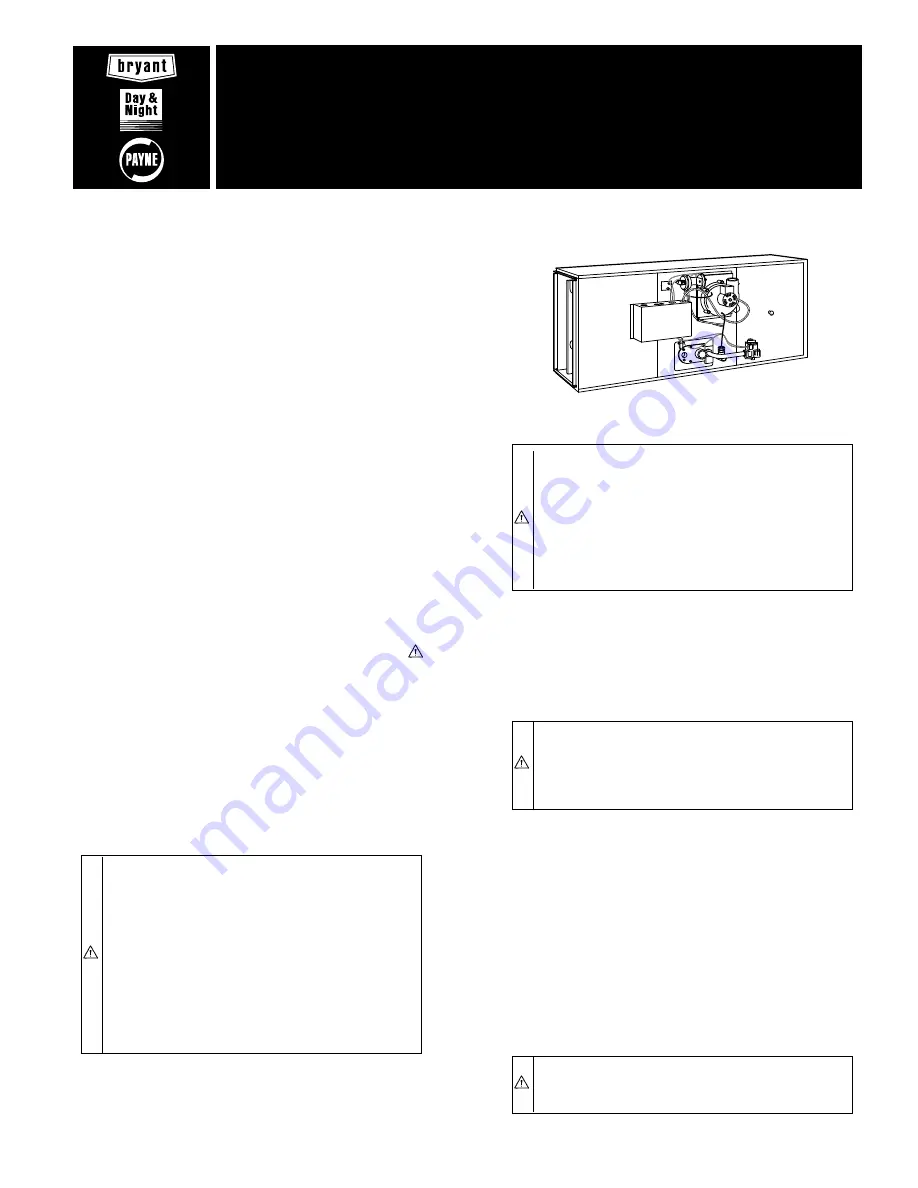

Fig. 1—Model 349MAZ Horizontal Furnace

A91174

service and

maintenance procedures

DELUXE GAS-FIRED

HORIZONTAL CONDENSING FURNACES

Cancels:

SP05-11

SP05-17

2-15-94

349MAZ

Series A

—1—