Summary of Contents for R2000

Page 1: ...1 Robusta SC Cantilever sliding gates Robusta SC Installation Manual ...

Page 11: ...11 Robusta SC 4 1 1 Automatic version right opening ...

Page 12: ...12 Robusta SC 4 1 2 Automatic version left opening ...

Page 13: ...13 Robusta SC 4 1 3 Motorizable version right opening ...

Page 14: ...14 Robusta SC 4 1 4 Motorizable version left opening ...

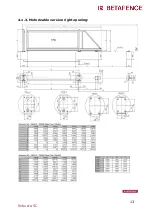

Page 15: ...15 Robusta SC 4 1 5 Manuel version right opening ...

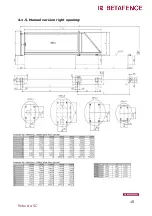

Page 16: ...16 Robusta SC 4 1 6 Manuel version left opening ...