1

E12317-00

E12319-00

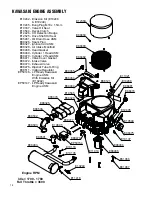

OPTIMA QT SERIES

OPTIMA QT SERIES

21”, 24", 27"

Propane Burnishers

Operator and Parts

Manual

1001 Brown Avenue • Toledo, Ohio 43607-0127

Customer Service: 888-GO-BETCO • Fax: 800-445-5056 • Technical Service: 877-856-5954 • www.betco.com

E12321-00

Optional

Emissions

Kit Available

Summary of Contents for Optima QT E12317-00

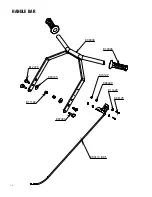

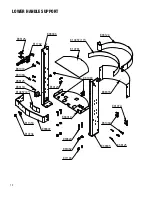

Page 10: ...10 HANDLE BAR ...

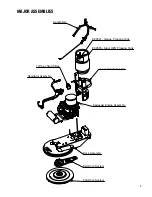

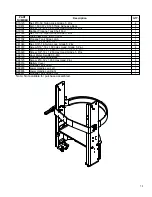

Page 12: ...12 LOWER HANDLE SUPPORT ...

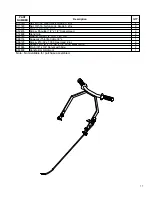

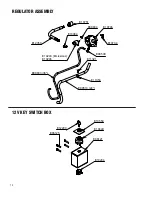

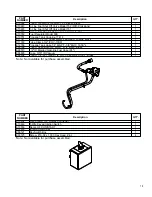

Page 14: ...14 PLVVLRQV REGULATOR ASSEMBLY 12V KEY SWITCH BOX ...

Page 34: ...34 ...

Page 35: ...35 ...