Model 2001SS Spray Gun

OPERATION AND MAINTENANCE INSTRUCTIONS

CONTROLLING THE FAN SPRAY:

The fan spray for an external mix nozzle

set-up is easily controlled by means of

the Side Port Control 54-3347. Turning

this control to the right, or clockwise,

until it is closed will give a round spray;

turning it to the left, or counterclockwise,

will widen the spray into a fan shape of

any width desired. The direction of the

fan spray, either horizontal or vertical, is

obtained by turning the air nozzle to the

desired position, then tightening the

retainer ring.

CONTROLLING THE FLUID:

If a fluid

pressure tank is used, the amount of fluid

can be controlled by regulating the

pressure on the tank. The amount of fluid

can also be controlled by means of the

Fluid Control 54-1007. Turning this screw

to the right, or clockwise, reduces the

amount of fluid; to the left, or counter-

clockwise, increases the amount of fluid.

FAULTY SPRAY:

A faulty spray is

caused by improper cleaning or dried

material around the fluid nozzle tip or in

the air nozzle. Soak these parts in a sol-

vent that will soften the dried material

and remove with a brush or cloth. Never

use metal instruments to clean the air or

fluid nozzles. These parts are carefully

machined and any damage to them will

cause a faulty spray. If either the air

nozzle or fluid nozzle is damaged, the

part must be replaced before a perfect

spray can be obtained.

TO REPLACE THE FLUID PACKING:

Remove the Fluid Control Screw 54-1007,

Spring 54-1347 and needle. Then remove

the Fluid Packing Nut 56-164 and take

out the old packing with a small stiff

wire. Replace with new Packing 2-28.

To set packing, insert needle, tighten nut

until the needle begins to be too stiff for

the spring to move needle. Then loosen

nut 1/2 to 3/4 turn.

CORRECTING AIR LEAK

THROUGH GUN:

Air leaking through

the gun is caused by the Valve Stem

Assembly 54-1025, not seating properly

against the Valve Body 54-1010.

Remove the Valve Body 54-1010 and

Valve Stem Assembly 54-1025.

Thoroughly clean parts and inspect for

damage. Replace worn or damaged parts

and assemble in reverse order.

CORRECTING AIR LEAK AROUND

AIR VALVE STEM:

Air leaking around

the Air Valve Stem 54-1025 may be caused

by worn Packings 8-158 or damaged

Air Valve Stem 54-1025. Remove Trigger

54-1050, Packing Nut 82-135 and Packings

82-158. Clean extended portion of

Air Valve Stem 54-1025 and inspect

for damage; if stem is damaged, replace

same as above, insert new packings and

assemble in reverse order.

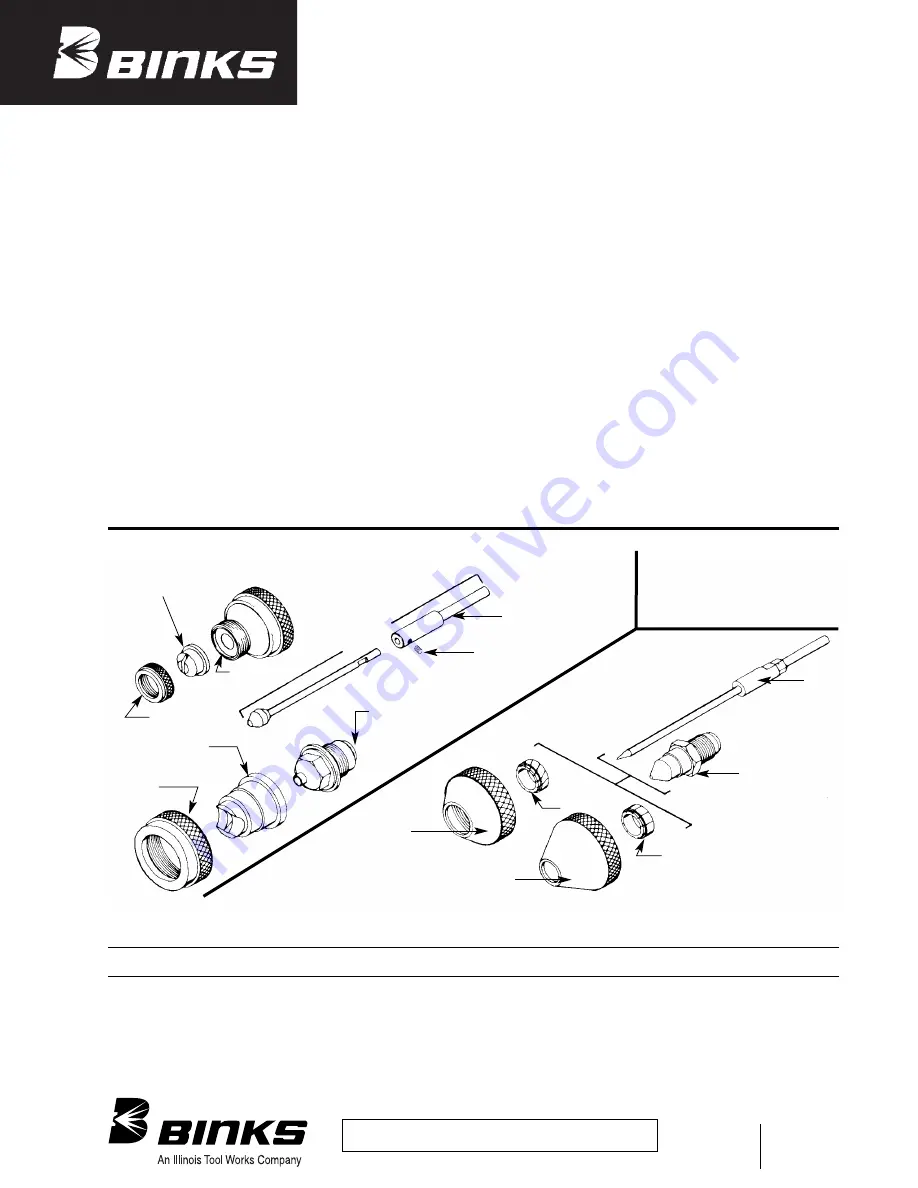

(Order Separately)

SPECIAL NOZZLES

SPECIAL EFFECT NOZZLES

FLUID NOZZLE

(See Chart)

#794 FLUID NOZZLE

#590

NEEDLE

VALVE

VEILING

DISTRESSING

AIR NOZZLE

(See Chart)

#797 AIR NOZZLE

#793

AIR NOZZLE

#54-2065

RING

#790

CORE

#792

SPIRAL

CORE

#54-1583

BASE

#559 NEEDLE

ASSEMBLY

#54-1227 GUIDE

#54-1584 RING

*NOZZLE TIP:

200 SERIES, NITRALLOY

#20-2093 SCREW

INTERNAL MIX HEAVY MATERIAL

Replaces

Part Sheet

2354R-3

Part

Sheet

77-2354R-4

6/05 © 2005 Illinois Tool Works Inc. All rights reserved. Printed in U.S.A.

ITW Industrial Finishing

Binks has authorized distributors throughout the world. For technical

assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-888-246-5732

ITW Automotive Refinishing

Binks has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S./Canada Customer Service Office:

1724 Indian Wood Circle, Suite J-K, Maumee, OH 43537

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

2354R-4 Revisions:

Changes made to text and illustrations related

to new 1-piece fluid needle design.

Binks Worldwide Sales and Service Listing: www.binks.com

WARRANTY

This product is covered by Binks’ 1 Year Limited Warranty.