Replaces

Part Sheet

77-2709R-10

Part

Sheet

77-2709R-11

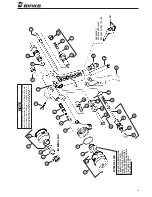

Binks Model 7N

Spray GuN

Binks Model 7N Gun is a rugged, light weight, hand held

Spray Gun, for applying gel-coats and polyester resins.

Catalyst is introduced to the material stream through the

atomizing air as the resin flows from the Material Nozzle.

Flow rate of the Gun varies up to 2 GPM depending on

nozzle selection. The actual fluid output is controlled by

nozzle orifice size and fluid pressure.

Nozzle TyPeS

Internal Mix—Low to high material volume,

low air consumption.

External Mix—Low material volume, fine

atomization.

Spray patterns are determined by the nozzle selection and

vary somewhat depending on size, angle, nozzle orifice and

output. External mix nozzle pattern cannot be changed

because this gun does not have a side port control.

However, its spray fan pattern can be rotated through 360°

by loosening the Retaining Ring, and rotating the Nozzle

Body, Item 1.

Faulty spray patterns can be caused by:

1. Foreign material in Air and/or Fluid Passages.

2. Viscosity too high for spraying. Air supply

or pressure inadequate.

3. Worn or damaged Nozzle surfaces.

4. Gellation in Gun Head Air Passages.

5. Gun Head Check-Valve, Items 6, 7, 8 frozen.

GuN CleaNiNG

Submerging the Gun in solvent will not harm the Gun;

however, it can adversely affect the Nozzle “O” Ring, Item

2. Submerging is poor practice because of the solvent resi-

due that may cling to interior air passages. Clean solvent

MUST be used if the Gun is to be submerged. The best

practice is to remove the Air Nozzle and to flush solvent

through the fluid passages. All Nozzles may be placed in

solvent for washing. The Nozzle Orifice and angle passage

ways are critical. Always wash and rinse with a clean sol-

vent to prevent residue accumulation in the minute holes.

NEVER use metal instruments for cleaning.

CheCk-ValVe CleaNiNG

A Check-Valve in the Head of the Gun prevents resin from

backing up into Air/Catalyst Passage. However, resin build-

up periodically may cause the Ball to freeze in the Head.

To free Ball:

1. Remove Plug, Item 11, Fluid Needle Assembly,

Item 16, and Packing Nut, Item 38.

2. Insert Wrench, Part No. 73-165, and turn counter-clock-

wise to remove Head, Item 5, and Check-Valve

Components, Items 6, 7, and 8.

3. Clean as required and reassemble.

Exterior surfaces of Gun should be kept clean by

wiping with a solvent-wet cloth.

ReSiN PaCkiNG

Packing take-up is accomplished by tightening Packing

Nut, Item 38, with a wrench. Packing replacement is

simple; proceed as follows:

1. Remove Fluid Control Screw, Item 17.

2. Remove Needle Assembly, Item 16.

3. Remove Packing Nut, Item 38, and old Packing,

Item 37, from Cavity.

4. Insert new Packing in Cavity.

5. Reassemble items removed in (1), (2) and

(3) above.

6. Set Packing, Item 37, by tightening Packing Nut,

Item 38, until Needle movement, Item 16, is

resisted, then loosen approximately 1/2-3/4 turn.

aiR leakS:

Through Gun head

1. Leaky Air Valve, Item 28.

Inspect, clean, or replace.

2. Air Valve Body, Item 30, not seated. Tighten.

3. Air Valve Body Gasket, Item 26, missing or damaged.

Replace.

4. Damaged Seat surface in Gun Body, Item 22. Replace.

at air Catalyst Valve, item 28

1. Around Air Valve Stem, Item 29. Tighten or replace

Packing, Item 31.

2. Damaged Air Valve Stem. Inspect and replace if

necessary.

3. Damaged Seat surfaces. Attempt repair with PTFE tape.

Replace if necessary.

NOTE

Needle lock Nuts, on the 59SS Needle, must be first removed

from the rear of the Needle, and the Needle then extracted

from the head end of the Gun. The 68SS Needle can be pulled

out from the rear of the Gun.

Summary of Contents for 7N

Page 7: ...NOTES 7 ...