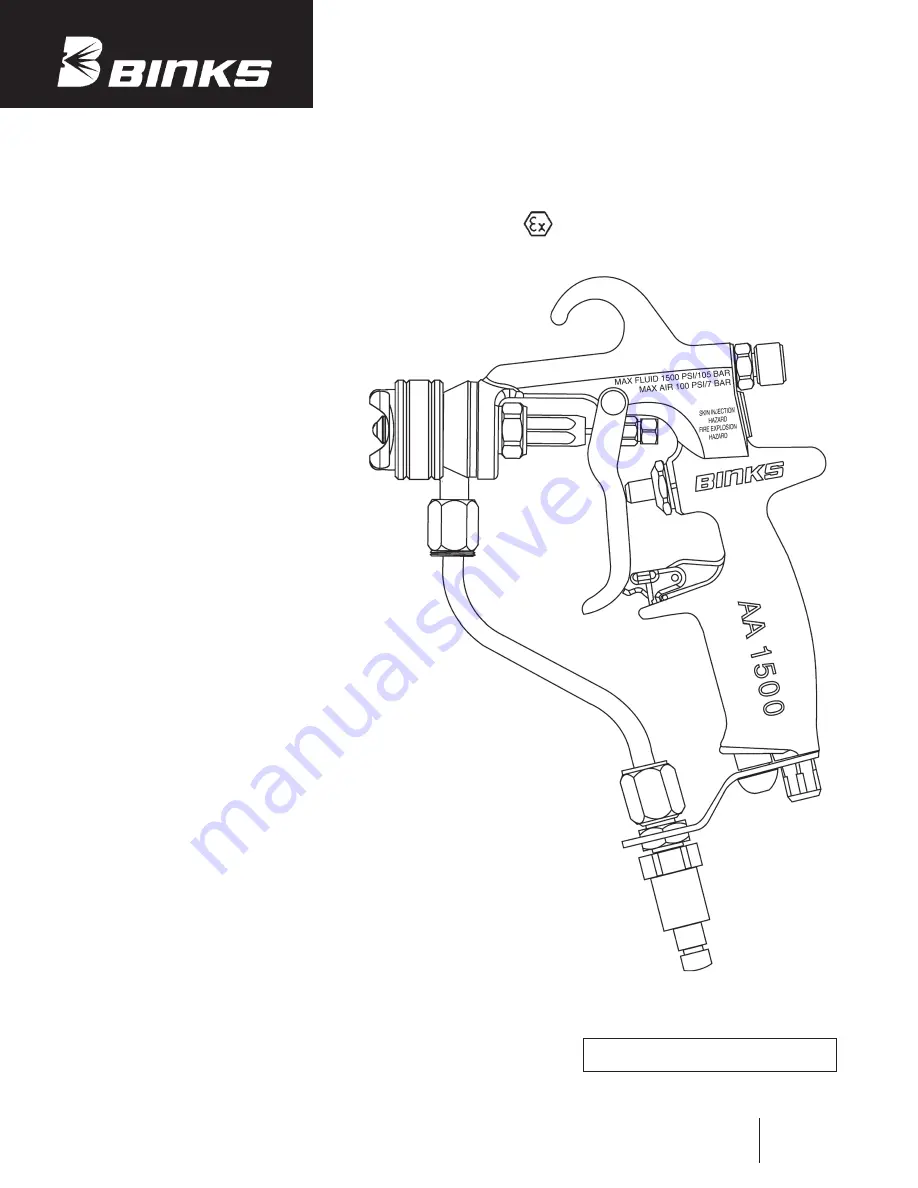

AA1500 AIR-AssIsted

AIRLess spRAy Gun

(wIth AA10 AIR AIR CAp And

FAn sIZe AdJustMent FeAtuRe)

Part

Sheet

77-2838R-4

The following instructions provide the

necessary information for the proper

operation and preventive maintenance

of the Binks AA1500 Air-Assisted

Airless Spray Gun. Please read and

understand all information in this

document in order to get the maximum

performance from your new AA1500

spray gun.

In the AA1500 spray gun, the paint or

other material to be sprayed is preatom-

ized and forced through the carbide tip

by the typical 400-800 psi fluid

pressure (with capabilities up to 1500

psi/105 bar). As a result of the preatom-

izing, the final shaping air supplied by

the air cap produces an exceptionally

fine and even spray pattern. The result

of this spray pattern is an even finish

that lends itself to products that need an

exceptionally fine finish with reduced

overspray and VOC emissions.

SPecificationS:

Maximum

Fluid Pressure:

1500 psi/105 bar

Maximum

Air Pressure:

100 psi/6.8 bar

Gun Body:

Forged Aluminum

Fluid Path:

Stainless Steel

Fluid

Shut Off Type:

Stainless Steel Ball,

Standard UHMW

Seat or optional

Tungsten Carbide

Fluid Inlet Size:

1/4" NPS(m) Thread

Air Inlet Size:

1/8" NPT(m) x 3/8"

O.D. Push In Tube

Fitting

Gun Weight:

16-oz.

Replaces

Part Sheet

77-2838R-3

Product shown is covered by U.S. patent no. 6,276,616.

foreign patents are issued or pending.

ii 2 G X