OPERATING INSTRUCTIONS:

The following steps and recommendations should be

followed to get the best results from your spray gun:

1. Connect high pressure airless fluid hose to the

gun fluid inlet and tighten securely.

2. With nozzle tip removed, start pump slowly

and direct spray gun into material container and

pull trigger until fluid flows steadily from gun.

3. Release trigger. Install nozzle tip per safety

procedure.

4. Increase pressure of pump and test spray

pattern for proper atomization.

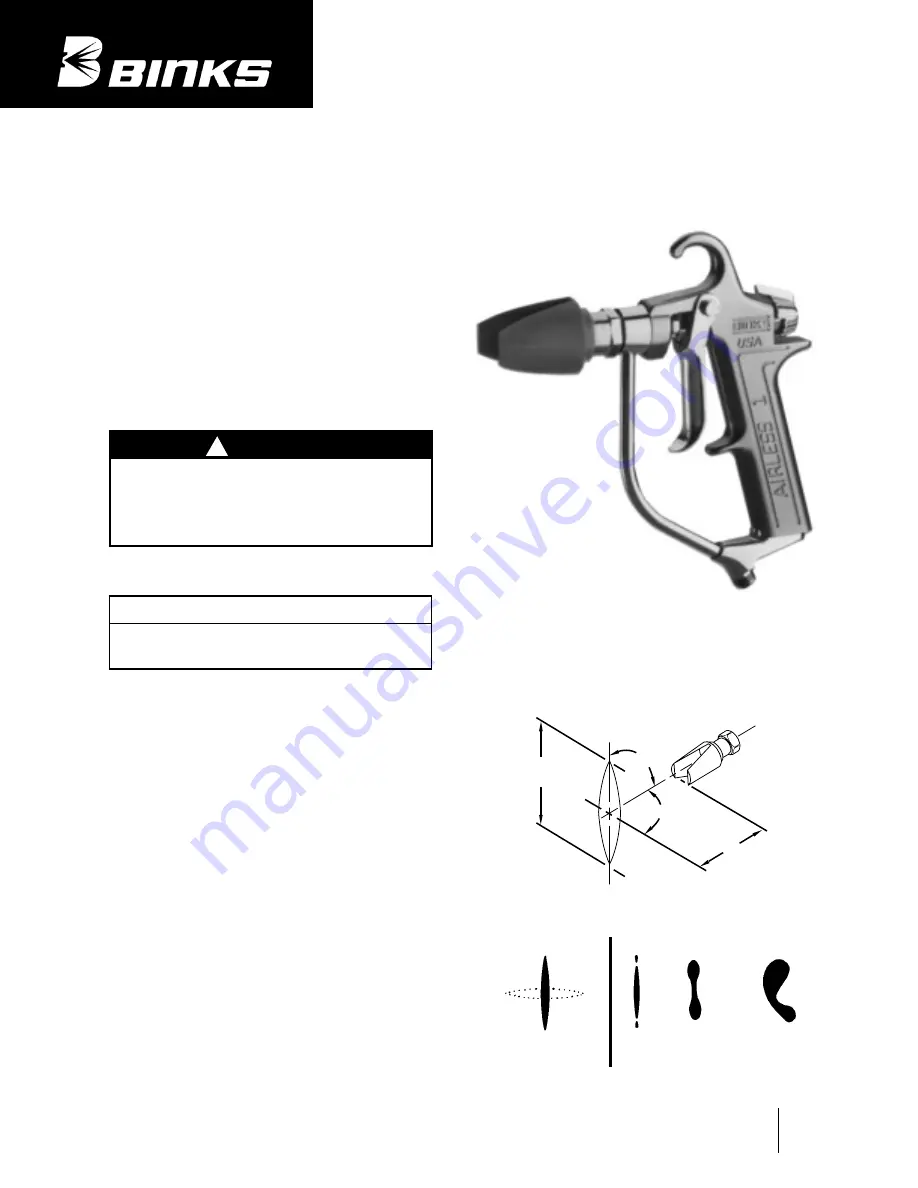

5. Spray gun distance from work surface should

be at a point where maximum fan pattern is

evident. This distance is normally 8 to 14

inches.

6. “Hour-glass” and “tails” on spray patterns

normally indicate too low a fluid pressure for

the nozzle tip orifice size, or the material is

too viscous or thick.

7. Distorted spray patterns may be the result of

excess fluid pressure, plugging of tip, or a

worn tip.

8. Airless spray guns are either ON or OFF. You

cannot “feather” with airless guns as you can

with air atomized equipment.

9. Successive strokes may not require over-lapping

as much as with air atomized spray because

of the heavier pattern edges produced by

airless spraying.

10. Spray strokes with airless spray guns will be

faster because of the higher fluid output.

Binks AIRLESS 1

SPRAY GUN

(For Professional Use Only)

Replaces

Part Sheet

2340R-5

Part

Sheet

2340R-6

WARNING

UNDER NO circumstances should the spray gun be care-

lessly handled nor its spray (even when nozzle is

removed) directed at close proximity to any part of the

human body. If you spray yourself or anyone else at

close range, the stream of material can puncture the

skin and cause great harm (possible amputation).

!

NOTE

Excessive fluid pressure will distort the spray pattern. A

simple rule to remember is “When the pattern is right,

the pressure is right”.

Your new Binks Airless 1 spray gun has been thoroughly

tested before leaving the factory. No adjustment is

required prior to spray operations other than installing

the nozzle tip.

CORRECT PATTERN

INCORRECT PATTERNS

“Tails”

“Hour-

glass”

“Distortion”

Maximum

Fan Width

Center Line

of Gun

90º

90º

8"

to

14"

OPERATION AND MAINTENANCE INSTRUCTIONS