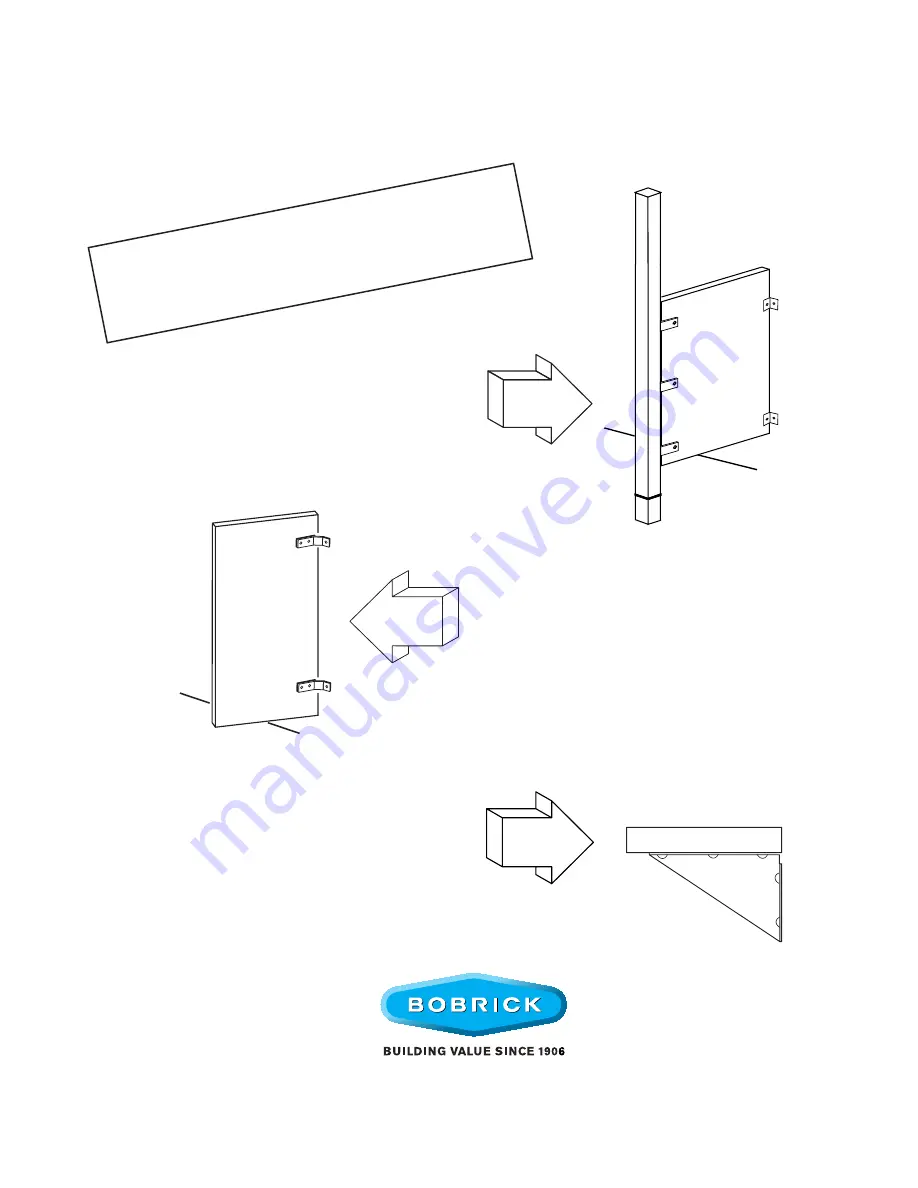

INSTALLATION INSTRUCTIONS

URINAL SCREENS, BENCHES & SHOWER SEATS

WALL

HUNG

BENCHES &

SHOWER SEATS

IMPOR

TANT:

Storag

e and Handling Inf

ormation on last pa

ge.

Review these instructions thor

oughly prior to

installation.

POST-TO

-CEILING

1033 Stainless Steel Edge

1043 High Pressure Laminate Edge

1083 Solid Phenolic

1183 Class A Solid Phenolic

1035 Stainless Steel Edge

1045 High Pressure Laminate Edge

1085 Solid Phenolic

1185 Class A Solid Phenolic

1545 Plastic Laminated Edge

1845 FRP

1040 High Pressure Laminate

1080 Solid Phenolic

1180 Class A Solid Phenolic