Installation

P.O. Box 309

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

215-1708 Rev. J; ECN 16-08-008

© 2016 Bradley

Page 1 of 13

6/2/2016

LVRD1

Verge

®

Lavatory System – LVRD-Series

with Evero

®

Natural Quartz Material

Table of Contents

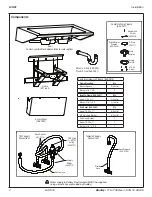

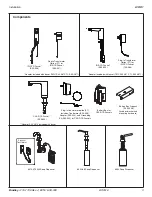

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–3

Supplies Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

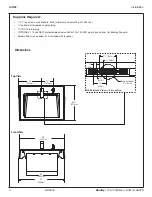

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–5

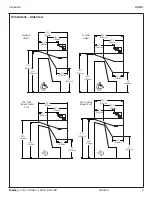

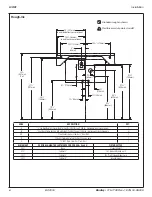

Rough-Ins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

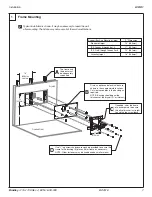

Frame Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

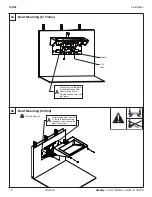

Faucet Box Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . .8

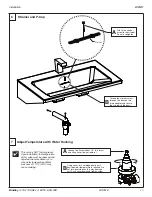

Drain Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Faucets and Optional Soap Valve . . . . . . . . . . . . . . . . .9

Bowl Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Strainer and P-trap . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Adjust the Temperature . . . . . . . . . . . . . . . . . . . . . . . .11

Trap Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . .13

U .S . Pat . No . D629,877

WARNING

Turn OFF electrical power to the electrical outlets, then unplug all electrical units prior to installation.

Electrical power MUST remain off until installation is complete.

Installer’s hardware must be appropriate for wall construction. Wall anchors must have a minimum pull-out

rating of 1,000 lbs.

NOTICE

Make sure that all water supply lines have been flushed and then completely turned off before beginning

installation. Debris in supply lines can cause valves to malfunction.

IMPORTANT

Read this entire installation manual to ensure proper installation. When finished with the installation, file

this manual with the owner or maintenance department. Compliance and conformity to local codes and

ordinances is the responsibility of the installer. Product warranties may be found under “Products” on our

Web site at bradleycorp.com.

Separate parts from packaging and make sure all parts are accounted for before discarding any packaging

material. If any parts are missing, do not begin installation until you obtain the missing parts.

For standard height mounting, do not exceed the recommended 34" distance from the top of the lav deck

to the finished floor. To meet ADA requirements, the lav deck cannot exceed the 34" maximum height

dimension.