NOTICE:

No warranty claims will be honored by CANARM Ltd. unless prior authorization is obtained

.

WARRANTY

CANARM Ltd. warrants every new product to be free of defects in material and workmanship, to the extent that, within a period of one

year from the date of purchase CANARM Ltd. shall either repair or replace at CANARM’s option, any unit or part thereof, returned freight

prepaid, and found to be defective.

This warranty does not include any labour or transportation costs incidental to the removal and reinstallation of the unit at the user’s

premises.Components repaired or replaced are warranted through the remainder of the original warranty period only.

This warranty applies to the original purchaser-user only; it is null and void in case of alteration, accident, abuse, neglect, and operation

not in accordance with instructions.

Installation or Product problems? Do not return to store of purchase.

Contact Canarm Service at 1-800-265-1833 (CANADA) 1-800-267-4427 (U.S.A.)

1-800-567-2513 (EN FRANCAIS) Monday to Friday 8:00 - 5:00pm e.s.t.

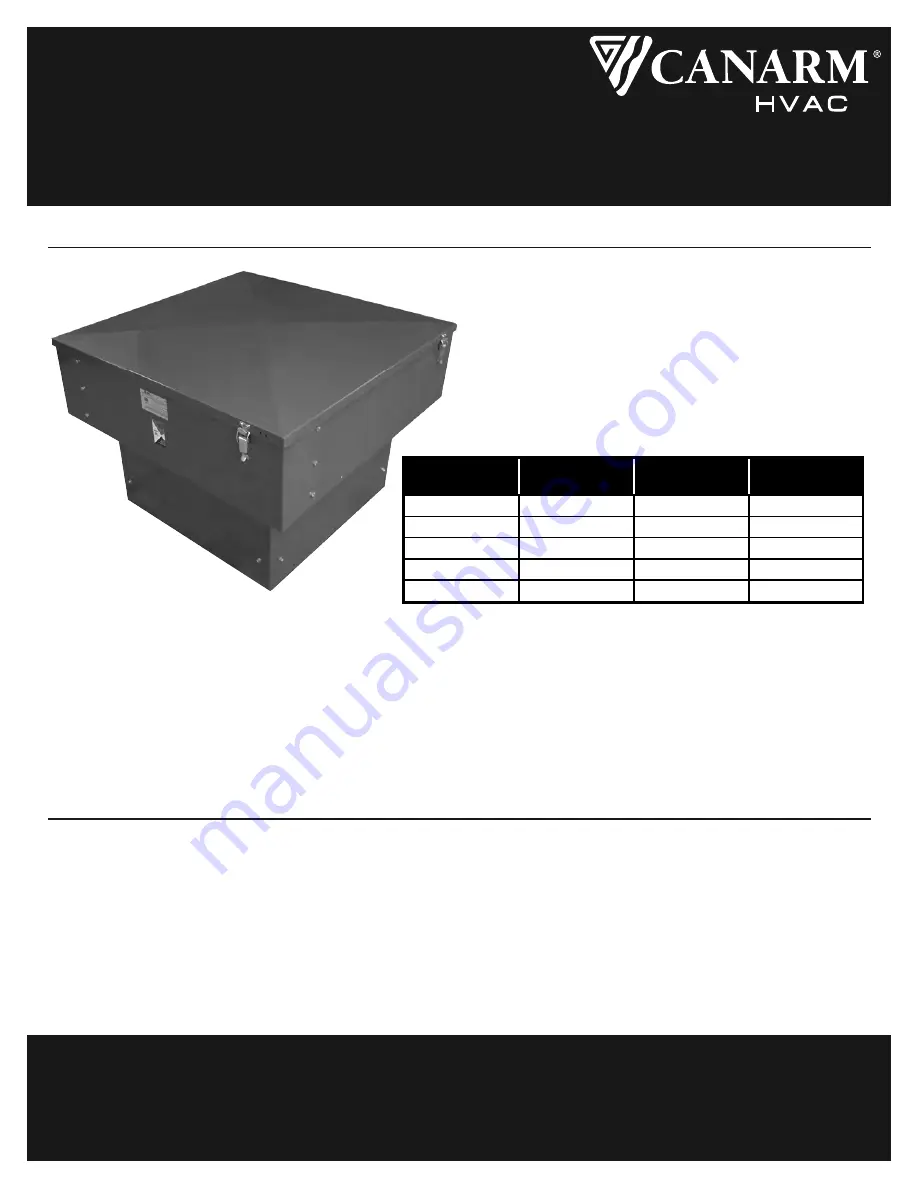

700 SERIES

FILTERED FRESH AIR SUPPLY UNITS

OPERATION INSTRUCTIONS

PLEASE READ AND SAVE THESE INSTRUCTIONS

700 SERIES MODELS: 709, 710, 712, 715, 718

GENERAL SAFETY

Rotating parts, (pulleys, shafts and belts) on fans should not be exposed. Where these components are not protected by ductwork, cabinets

or covers, appropriate guards should be employed to restrict exposure to rotating parts. Access doors should not be opened with the fan

operating to avoid foreign objects being drawn into the system. On initial start-up, a careful inspection should be carried out to ensure no

foreign material is present which could become airborne in the system.

Read installation and operation instructions carefully before attempting to install, operate or service Canarm/Delhi 700 Series. Failure to

comply with instructions could result in personal injury and/or property damage.

Retain instructions for future reference.

700 SERIES_06_14_2022

Page 1 of 4

MODEL

MAX. HP

SHAFT

DIAMETER

WEIGHT

709

1.5

3/4"

155 lbs

710

1.5

3/4"

204 lbs

712

2

3/4"

247 lbs

715

3

1"

267 lbs

718

5

1"

370 lbs