lefty speed

dlr2 & sl

Owner’s Manual Supplement

120025.PDF

READ THIS MANUAL CAREFULLY!

It contains important safety information.

Keep it for future reference.

CONTENTS

SAFETY INFORMATION ...........................

About This Supplement .......................

2

Safety Messages ....................................

2

Intended Use ..........................................

3

Warning Label ........................................

3

Intended Use ..........................................

3

Bicycle Suspension ................................

3

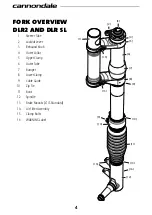

FORK OVERVIEW ...................................

4

Rebound and Lockout .........................

3

FRONT WHEEL ........................................6

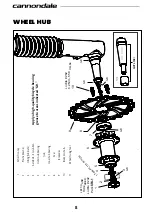

WHEEL HUB ...........................................

8

FRONT BRAKE ........................................9

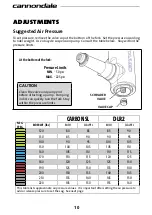

ADJUSTMENTS ......................................

10

Suggested Air Pressure ......................

10

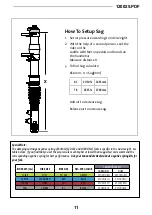

How to Set Up Sag ...............................

11

Rebound Adjuster ...............................

12

Lockout Lever ........................................

12

Tuning Tips ............................................

13

MAINTENANCE .....................................

14

Schedule ................................................

13

Cleaning ................................................

13

Air Filter .................................................

17

Frame Bumper .....................................

17

Fork Boot ...............................................

18

Needle Bearing Migration ...............

20

XC3

SI STEM STEERER ...........................

22

SUSPENSION GLOSSARY .....................

24

REPLACEMENT PARTS ...........................

27

DLR2

DAMPER ......................................

28

SL DAMPER ...........................................

30

TELESCOPE PARTS ................................

32

SERVICE TOOLS .....................................

33

OWNER NOTES ....................................

34

29

INCH WHEEL COMPATIBILITY .........

36

Please note that the specifications and information in this manual are subject to change for product

improvement. For the latest product information, go to

http://www.cannondale.com/tech/.