LOGIX

10

Series

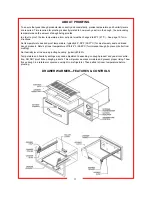

DUAL HUMIDIFIED HOLDING CABINET

with PAN SLIDES & TWO-DRAWER WARMER

MODEL: HL10-10-RW

(Formerly HWU10S1XE-RW & HWC20S1XE-RW)

OWNERS / OPERATORS MANUAL

Part Number: 18400-3172b Printed in The United States of America

Rev: KBA120512

TABLE OF CONTENTS

SAFETY

PRECAUTIONS

2

FEATURES

&

SPECIFICATIONS

3

UNPACKING, INSPECTION & FREIGHT DAMAGE

4

INSTALLATION

&

STARTUP

5

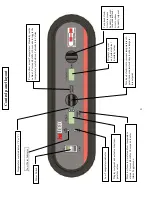

CONTROL PANEL LAYOUT

6

WATER

PROBE

ADJUSTMENT

7-8

NORMAL

OPERATION-HOLDING

CABINET

9-10

ABOUT PROOFING

11

NORMAL

OPERATION-DRAWER

WARMER

11-13

FOOD HOLDING GUIDE

14

REGULAR

CLEANING

PROCEDURES 15-16

MAINTENANCE

17-18

WIRING DIAGRAM

19

TROUBLESHOOTING GUIDE

20

WARRANTY STATEMENT

21

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 U.S.A.

Phone: 847-362-5500

Fax: 847-367-8981

Toll Free: 800-323-9793

Email: technicalservice@carter-hoffmann.com

READ THIS MANUAL COMPLETELY

BEFORE OPERATING THIS APPLIANCE

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to

be given to the OWNER of MANAGER, or to the person respon-

sible for training operators of this appliance.

THIS MANUAL IS TO BE UNDERSTOOD BY ALL PERSONS

USING OR INSTALLING THIS APPLIANCE.

Contact Carter-Hoffmann if you have questions regarding instal-

lation, operation or maintenance of this equipment.

HL10-10-RW

with optional glass door