Equipment Issue 2

Fourth Printing, March 2016

Section LTCMPH-75-802

E

Copyright 2012

−

2016 Charles Industries, Inc. All rights reserved. Printed in the United States of America.

Charles

r

is a registered trademark of and CMPH

t

is a trademark of Charles Industries, Ltd. Availability of features and technical specifications herein subject to change without notice.

Page 1 of 5

0316P4

Charles Multi-Purpose Housing (CMPH

t

)

Enclosure

Installation Instructions

1.

GENERAL

1.1

Document Purpose

This document provides installation instructions for the Charles Multi-Pur-

pose Housing (CMPH

t

) enclosure, which provides a quick and easy way to

attach, mount, and protect various types and quantities of copper and fiber

cables, splices, cases, and equipment in a protective, outside plant (OSP),

above-ground enclosure. See Figure 1 for a typical CMPH model, Table 5

for general information on products in this series, or call Charles Indus-

tries (see Part 2) to request more information.

- NOTE -

Hereafter the Charles Multi-Purpose Housing will be commonly referred to as

the “CMPH” or “enclosure.”

1.2

Document Status

Whenever this document is updated, the reason will be stated in this para-

graph. The Fourth Printing removes “Optional Stake Mounting”. Stake

mounting is required for best performance.

1.3

Product Purpose and Description

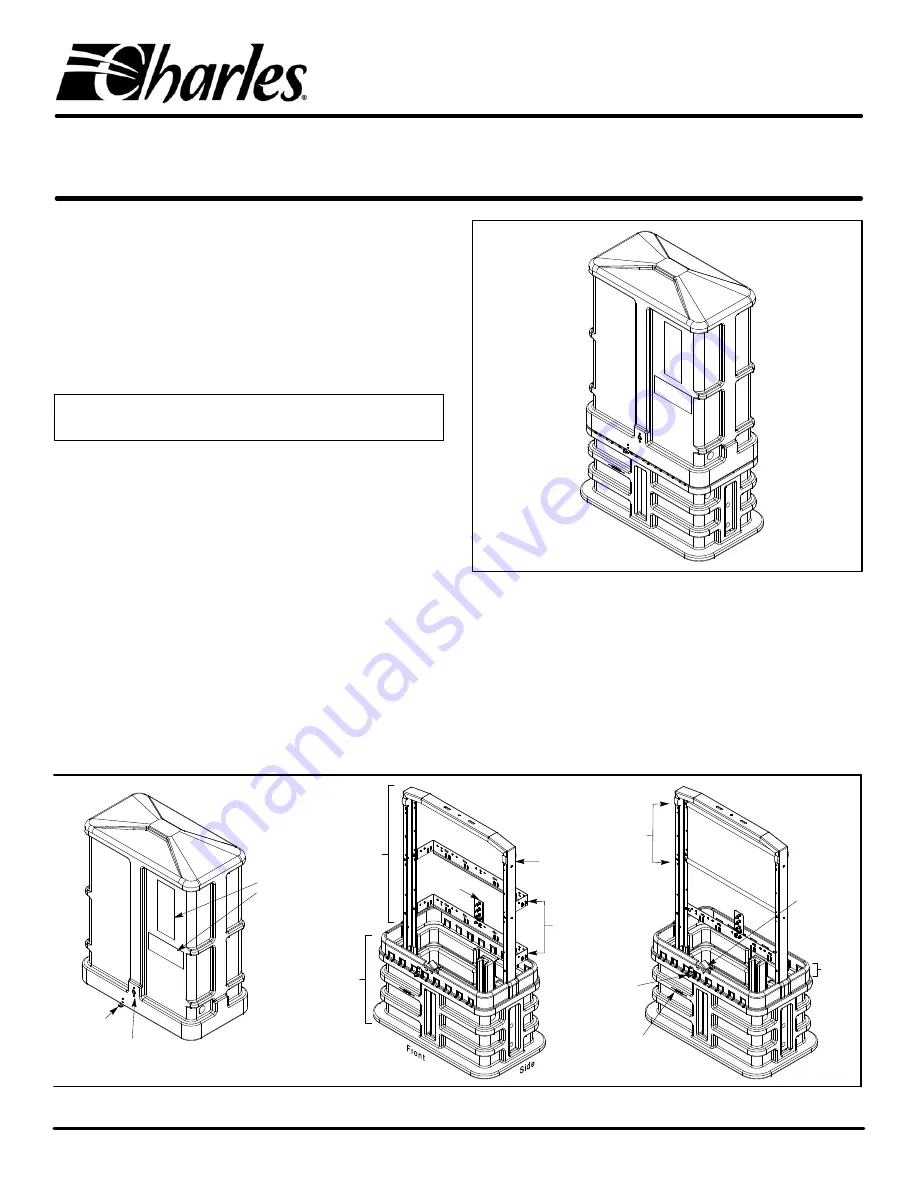

The CMPH is a non-metallic, two-piece, rectangular, OSP enclosure that

offers easy installation, superior structural strength, 360

_

technician ac-

cess, generous internal equipment and cable storage capacity, and

protection against corrosion, floods, fire, weather, dirt, insects, intrusion,

dents and impact. The CMPH contains a base, a dome, and internal frame-

work. The base has corrugated or ribbed walls, internal, dual-purpose,

molded-in, channel grooves (which accept most metallic stakes as well as

the vertical channels of the internal framework, see Figure 2), an open top,

and an open bottom. Easy replacement installations and easy underground

cable access is provided via the open bottom. The top piece of the CMPH

is the dome, designed to overlap the base for a flood-protective bell-jar ef-

fect. Inside the CMPH, sturdy framework with splice bars and brackets

provides versatile mounting options for equipment (such as fiber optic

Figure 1. Typical CMPH Enclosure, Closed View

splice closures, terminal blocks, and cases) as well as storage, contain-

ment, and attachment options for various types, sizes, and quantities of

conduit, innerduct, and cabling.

1.4

Product Mounting Type and Location

The CMPH is an above-grade enclosure, the base of which is typically in-

stalled in a trench or hole in the ground up to the base’s ground line indicator.

The ribbed or corrugated base walls provide excellent stability in most soil

types. The dome mounts on the base and protects all equipment installed or

Figure 2. Typical CMPH Enclosures, Dome Removed Views

Dome

Base

Inside

Framework

Fiber cable

management

offset brackets

Channel

Hasp

(see Step 26)

Ground

Plate

Hasp

(optional)

Base

collar

Copper cable

management

bars

Fiber-type

Copper-type

Label or

decal

areas

Self-locking latch

(secured via cup‐washer screw)

Ground line

indicator

Base latch

(lock

catch)