LT-WIC101010

3

rd

Printing, July 15, 2020

©Copyright 2020 Charles Industries LLC. All Rights reserved. Printed in the United States of America.

Availability of features and technical specifications herein are subject to change without notice.

Charles is a registered trademark of Charles Industries.

Page 1 of 16

Charles Universal Broadband Enclosure

WIC-101010SXAN1

General Description and Installation

GENERAL INTRODUCTION ...................................................... 1

Document Purpose ................................................................... 1

Product Purpose ....................................................................... 1

Product Mounting and Location ............................................... 1

PRODUCT DESCRIPTION ........................................................... 2

INSTALLATION ............................................................................ 6

Inspecting the Product .............................................................. 6

Following and Using Safety Precautions.................................. 6

Obtaining Tools and Equipment ............................................... 6

Preparing the Installation Site .................................................. 6

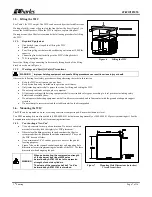

Lifting the WIC ......................................................................... 7

Mounting the WIC .................................................................... 7

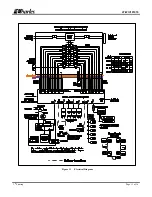

WIC Wiring and Equipment.................................................... 10

Conduit Seals.......................................................................... 13

Verifying the Installation ........................................................ 13

PERIODIC MAINTENANCE ...................................................... 13

TECHNICAL ASSISTANCE AND REPAIR SERVICE ........... 13

WARRANTY & CUSTOMER SERVICE ................................... 13

SPECIFICATIONS ....................................................................... 13

Regulatory Specifications ....................................................... 13

Product Specifications ............................................................ 14

Part Numbers ......................................................................... 14

Alarm Connections ................................................................. 15

1.

GENERAL INTRODUCTION

1.1.

Document Purpose

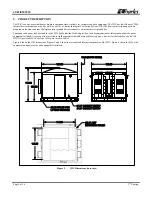

This document provides general information for the WIC-101010SXAN1 walk-in cabinet. Figure 1 shows a closed front view of the

enclosure.

-NOTE-

Hereafter, the Charles Walk-in Cabinet WIC-101010SXAN1 will be referred to as the “WIC.”

1.2.

Product Purpose

The WIC consists of a protective walk-in enclosure for an integrated system of electronic components and equipment that can serve fiber

and copper interfaces. Note: this enclosure is not intended for use as a dwelling and is not suitable for human or animal habitation.

1.3.

Product Mounting and Location

This enclosure is suitable for outside plant-type (OSP) locations and those that may require NEC compliance. The outdoor, weather-

resistant WIC is to be mounted on a concrete pad. The installer connects the power, fiber and copper connections. Detailed mounting and

installation information is covered in Section 3.

Figure 1

Front View of the WIC