4400H TwinHybrid

™

Gas Seal

Installation, Operation and Rebuild Instructions

TABLE OF CONTENTS

INSTALLATION, OPERATION and

REBUILD INSTRUCTIONS

Seal Data Reference

(Insert seal and equipment data here for future reference)

ITEM #

SEAL

(Example: 4400H – 50 mm SSC/CB/FKM/S)

INSTALLATION DATE

...................................................................

..........................................

...............................................................

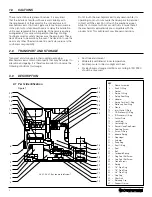

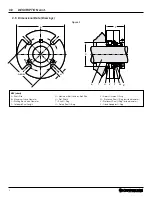

3.1 Parts Identification ..........................................................2

3.2 Operating Parameters .....................................................3

3.3 Standard Materials .........................................................3

3.4 Intended Use ..................................................................3

3.5 Dimensional Data ..................................................... 4 - 5

4.0 Preparation for Installation

...................................

.......................................................

6.0 Commissioning/Equipment Start-up

7.0 Decommissioning/Equipment Shut Down

..............................................................

9.0 Seal Maintenance and Repair

9.1 4400H Trouble Shooting .................................................8

9.2 4400H TwinHybrid™ Gas Seal Rebuild Instructions .. 9 - 11