Summary of Contents for 427

Page 1: ... 0 0 a a Z 0 0 0 m tJ Q l a E en en Z UI Z en en en CC E U ...

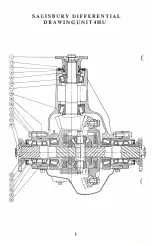

Page 9: ...00 I ...

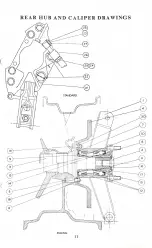

Page 12: ...REAR HUB AND CALIPER DRA WINGS 0 2 1 STANDARD 8 2 9 RACING 11 ...

Page 19: ... FRONT HUB AND CALIPER DRAWINGS 27 14 i15 I 6 STANDARD 13 if lI 14 15 16 I RACING 18 ...

Page 27: ... 1 i mm r 1l IJ c 1 1 0 1 __ I _ ___ I tv 0 RACK PINION ASSY R H II f0 13 I 17 ...

Page 48: ...e ARMATURE e ts Z u z IH 1t j d BEARING HOUSI NG BRUSH GEAR ...

Page 61: ...09 3HOU3 JOlId NIMOTIO 3HL l dOOV aor MOS NIO IO i N3HM ...