1

Form No. 256827 Rev. 11/08

SERVICE MANUAL

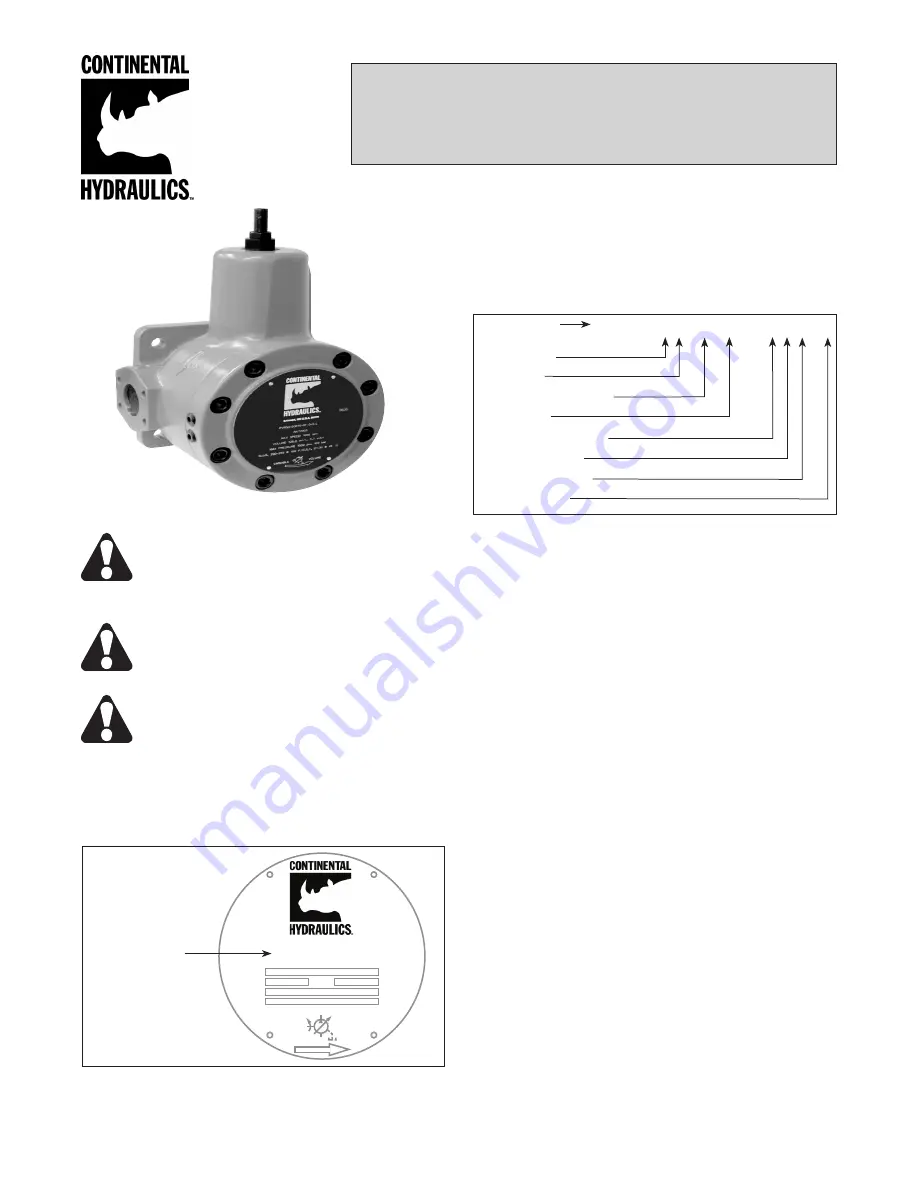

PVR50 Flanged Series Pump

Installation, Startup, Operating Instructions, Parts Pages, Repair Procedures

“L” Design Series

Basic Pump

Pump Size

Pressure

Rotation & Mounting

Seal Type

Mechanical Options

Control Options

Integral Operator

Design Letter

PVR50 - _ _ - _ - _ - 5 _ _ _ - L

Figure 1

Figure 2

PVR50-

RATINGS

S.U.S 200-250 @ 100°F./C.S.T. 21-30 @ 49°C.

r

rpm

v

IN

3

/r

p

psi

p

bar

m

l

/r

Model Code

50B15-RF-0-521-L

CAUTION

-

Before performing any service

operation on any pump, be sure that all

pressure has been relieved from BOTH

SIDES of the system.

CAUTION

-

Before performing any service

operation on any pump, disconnect or lock

off power supply.

CAUTION -

Before starting pump, be sure

that any resulting machine function will not

endanger persons or equipment.

PRODUCT IDENTIFICATION

Each pump has an Ordering Code stamped on its

nameplate. See Figure 1 for the location of the

Ordering Code.

This service manual applies to products with Ordering

Codes like the sample in Figure 2.

INSTALLATION

PUMP DRIVE AND MOUNTING

When mounting the pump and motor, care must be

taken to align the pump and motor shafts within .003

T.I.R. Direct inline through a jaw type/flexible web

coupling is recommended for all Continental pumps.

Tire-type flexing elements and chain-type drives are

not recommended. With belt drives, please consult

factory.

To avoid axial and radial end loading of the pump

shaft, do not couple the pump and motor shafts

rigidly. Allow freedom at the coupling for the two

shafts to ride independently.

To prevent end loading, the space between the pump

and motor shaft ends should be 3/4 inch (19.1 mm)

for PVR50 pumps, or as the coupling manufacturer

specifies.

PIPING AND RESERVOIR

The pump should be mounted with a minimum

number of elbows or fittings. The pump suction

should be at least two (2) inch (50.8 mm) tube/pipe

for PVR50 pumps and 2-1/2 inch (63.5 mm) tube/pipe

for PVR50-70B pumps.