GB 71812 00 / Issue 3 / 15

CUSTOMER CARELINE 01746 713410

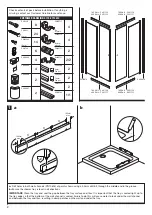

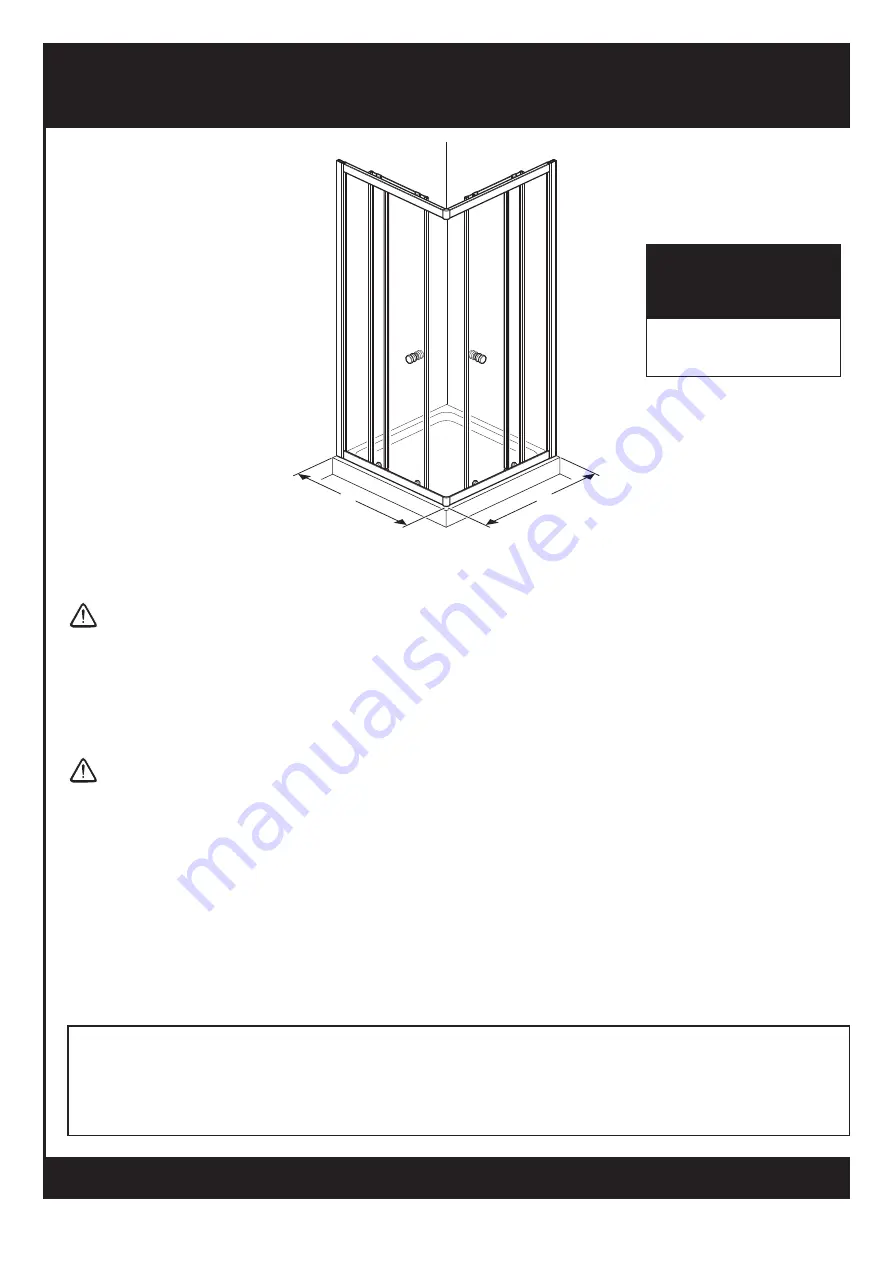

Equipment needed:

Drill, 6.5mm Masonry Bit, 4.5mm & 3mm Metal Bits (general), Crosshead Screwdriver, Right Angle, Fine Tooth Saw,

Spirit Level, Pencil, Scissors, Silicone Sealant, Tape Measure, Masking Tape.

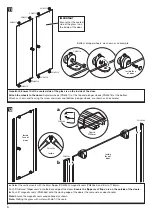

Note:

The screws and wall plugs supplied are for masonry walls. For lightweight walls i.e. stud partition, plasterboard etc,

use the correct type of fixings.

CORNER ENTRY

SHOWER ENCLOSURE

Please read these instructions carefully and keep for future reference.

Incorrect fitting will invalidate the guarantee.

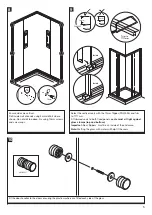

SAFETY

●

Handle glass with great care. Although the glass is very tough, sharp impacts can damage both the glass

and metal frame.

●

Make sure there are no hidden pipes or cables hidden in the wall where you intend to drill.

●

Wear safety goggles, shoes and appropriate clothing.

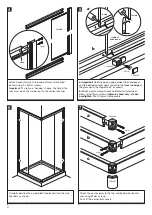

BEFORE INSTALLATION

●

Two people are needed to carry out parts of the procedure, lift with care.

●

Check that the shower tray is level in all directions. The enclosure will not sit correctly on an uneven surface.

If uneven, the wall channels may not fit and the doors may not shut correctly.

●

The shower tray and the enclosure must match in size. Attempting to fit the incorrect size of enclosure to the

shower tray will result in water leaks.

●

The enclosure should be fitted on tiled walls which are sealed with waterproof grout.

There must be a good silicone seal between the rim of the shower tray and the wall.

●

Always check very carefully that components are vertical.

●

To avoid damage, use the opened out packaging to build the enclosure on.

760 Door X =

740 - 760mm

800 Door X =

780 - 800mm

DIMENSIONS

Check the enclosure size in

the table below matches the

showertray installation.

X

X