Summary of Contents for 247.887801

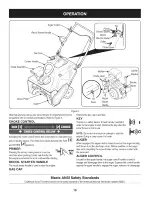

Page 20: ...Craftsman Snow Thrower IViodel 247 887801 2O ...

Page 22: ...Craftsman Snow Thrower Model 247 887801 8 22 ...

Page 26: ...Craftsman Engine IViodel 265 JU 11 For Snow IViodel 247 887801 46 I 47 2 _78 79 26 ...

Page 28: ...Craftsman Engine IViodel 265 JU 11 For Snow IViodel 247 887801 110 1 1 7 12 19 41 42 _42 28 ...

Page 30: ...Craftsman Engine IViodel 265 JU 11 For Snow IViodel 247 887801 26 28 _33 I_34 35 36 3O ...