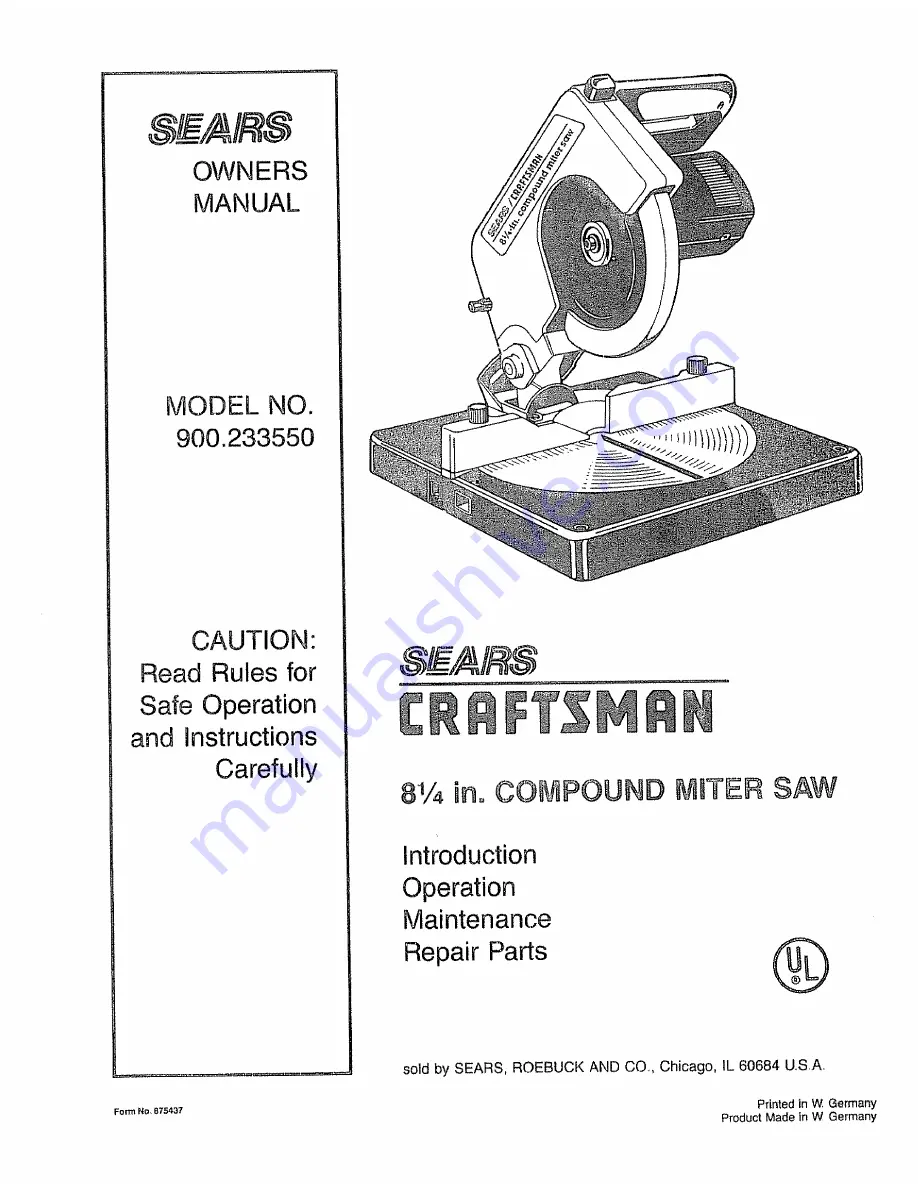

Reviews:

No comments

Related manuals for 900.233550

9683311

Brand: Palmgren Pages: 16

RPR 850

Brand: Roney Power Pages: 12

M12 CHZ-0

Brand: Milwaukee Pages: 9

PDKS 6.3 A1

Brand: Parkside Pages: 74

241-9853

Brand: KRAFTtech Pages: 23

HPRS011

Brand: HART Pages: 24

REDLEG 65313

Brand: JS Products Pages: 12

M18 FMS184

Brand: Milwaukee Pages: 12

3901244901

Brand: PRACTIXX Pages: 328

CTS315

Brand: Draper Pages: 24

SMS250AB

Brand: Draper Pages: 34

58G970

Brand: Graphite Pages: 84

2064

Brand: SAW TRAX Pages: 19

HC510DV

Brand: RedMax Pages: 44

1400102

Brand: GreenWorks Pages: 32

27112700

Brand: GreenWorks Pages: 28

SE-912

Brand: Dake Pages: 34

745365

Brand: DWT Pages: 133