A Crane Co. Company

INSTALLATION MANUAL

IMPORTANT!

Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

change product without prior written notifi cation.

420 Third Street

83 West Drive, Bramton

Piqua, Ohio 45356

Ontario, Canada L6T 2J6

Phone: (937) 778-8947

Phone: (905) 457-6223

Fax: (937) 773-7157

Fax: (905) 457-2650

www.cranepumps.com

Form No. 118951-Rev. J

Series: OGP2022CO

2 HP, 3450 RPM, 60 Hz.

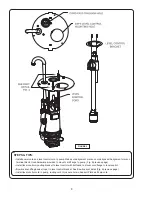

Fits into E-One 200:

2000 Series Basin

This product may be covered by one or more of

the following patents and other patent(s) pending:

US Patent 7,357,341 & 7,578,657

Fixed Discharge

Replacement Core Unit

Manual Index

Summary of Contents for Barnes PS Omni Grind Plus OGP2022CO Series

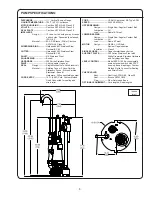

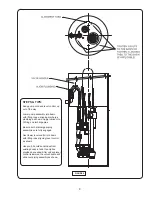

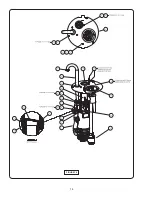

Page 11: ...11 FIGURE 8 ...

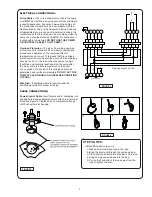

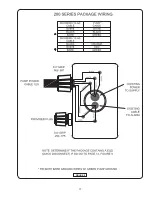

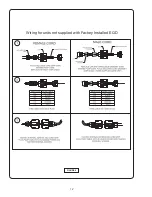

Page 12: ...12 FIGURE 9 Wiring for units not supplied with Factory Installed EQD ...

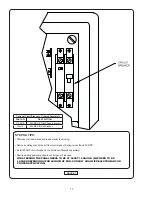

Page 13: ...13 Wiring for Optional Remote Alarm Light ...

Page 14: ...14 FIGURE 10 ...

Page 16: ...Notes ...