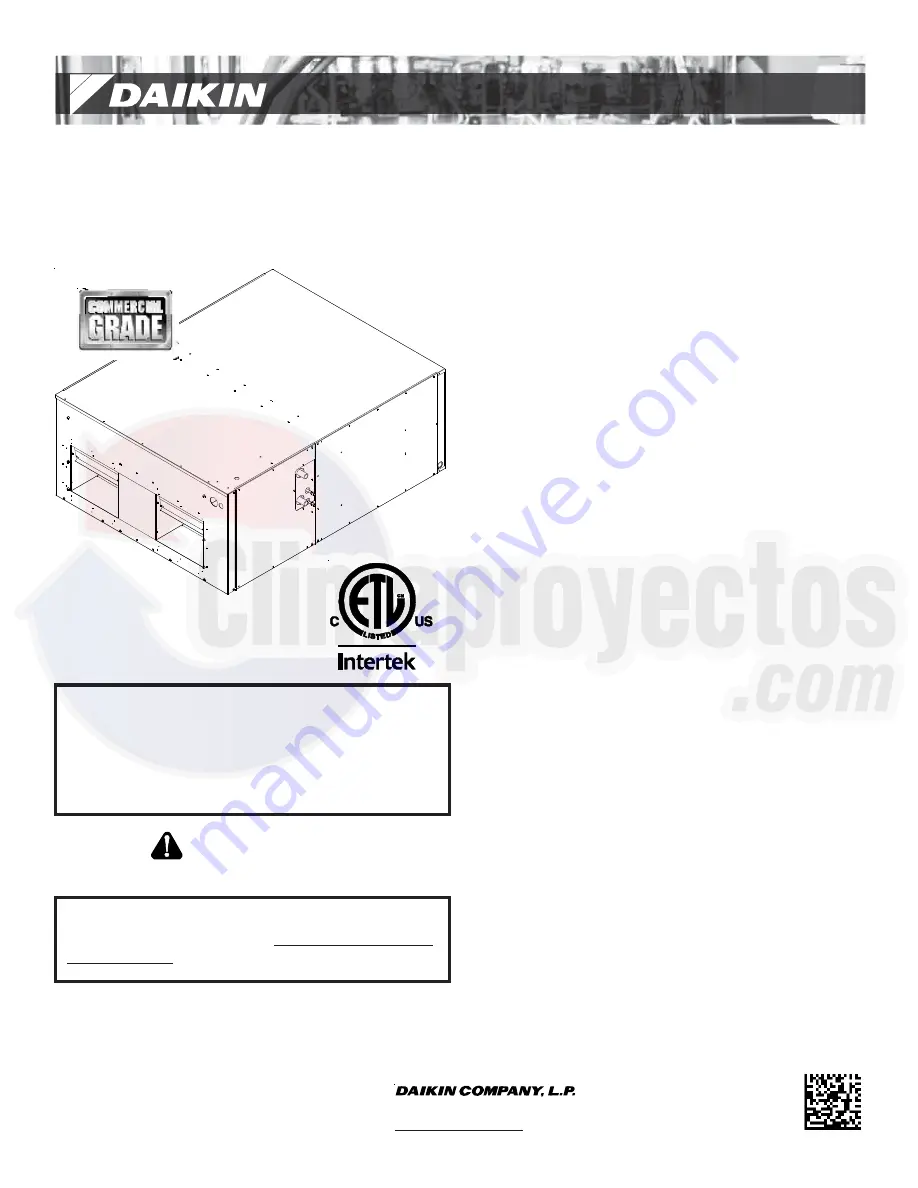

IMPORTANT NOTE:

DAR models are suitable for Upflow and Horizontal

Installations only. Do not use for Downflow Installations.

IOD-4010

6/2013

INSTALLATION INSTRUCTIONS

Our continuing commitment to quality products may mean a change in specifications without notice.

© 2013

5151 San Felipe St., Suite 500, Houston, TX 77056

www.daikincomfort.com

DAR

SERIES

COMMERCIAL AIR HANDLERS

ATTENTION INSTALLING PERSONNEL:

Prior to installation, thoroughly familiarize yourself with this

Installation Manual. Observe all safety warnings. During

installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to

educate the customer on its safe use.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION.

Index

Important Safety Instructions .............................................. 2

Product Identification .......................................................... 3

Product Description ............................................................. 3

Unit Inspection .................................................................... 3

Codes & Regulations ............................................................ 3

Replacement Parts ............................................................... 3

Pre-Installation Instructions ................................................. 3

Location ............................................................................... 4

Ductwork ............................................................................. 4

Supply Ductwork and Flanges ............................................ 4

Return Ductwork ............................................................... 4

Return Air Filters ............................................................... 4

Electric Heat ........................................................................ 4

Electrical Supply Wire and MOP ........................................... 5

Building Electrical Service Inspection ................................. 5

Wire Sizing ........................................................................ 6

Maximum Overcurrent Protection (MOP) .......................... 6

Conversion 0f 460 Electrical Power Supply ......................... 7

Electrical Connections .......................................................... 7

Supply Voltage .............................................................. 7

Air Handler Only (Non-Heat Kit Models) ....................... 7

Heater Kit Models ......................................................... 7

Low Voltage Connections .............................................. 8

Heat Kit Installation ............................................................. 8

Refrigerant Lines .................................................................. 8

Tubing Preparation ........................................................... 9

Post Brazing ...................................................................... 9

Piping Size ......................................................................... 9

Evaporator Coil TXV ........................................................... 10

Airflow ............................................................................... 10

Belt Tension ....................................................................... 10

Regular Maintenance ......................................................... 11

Wiring Diagram .................................................................. 12