Summary of Contents for UAL-A Series

Page 8: ...7 Dimensions Unit mm WATER IN WATER OUT UAL WATER IN WATER OUT UAL UAL ...

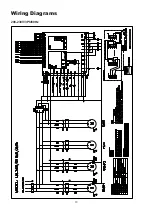

Page 14: ...13 Wiring Diagrams 208 230V 3Ph 60Hz ...

Page 15: ...14 ...

Page 16: ...15 ...

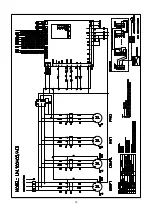

Page 17: ...16 460V 3Ph 60Hz ...

Page 18: ...17 ...

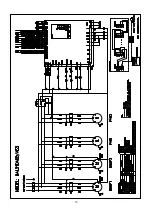

Page 19: ...18 380V 3Ph 60Hz ...

Page 20: ...19 ...

Page 21: ...20 ...

Page 38: ...37 220V 1Ph 60Hz Wired Controller Instruction Dimensions Controller Installation ...