KAT- T313-004

J a m ( T u r n O v e r )

J a m ( H o p p e r )

H R i s t o o h o t .

P l e a s e r e m o v e

M E D I A F I L M

P l e a s e ,

P o w e r O f f .

> I n k >

> C l e a n i n g

> C o u n t e r R e s e t

> D i s p l a y >

R e a d y

MENU

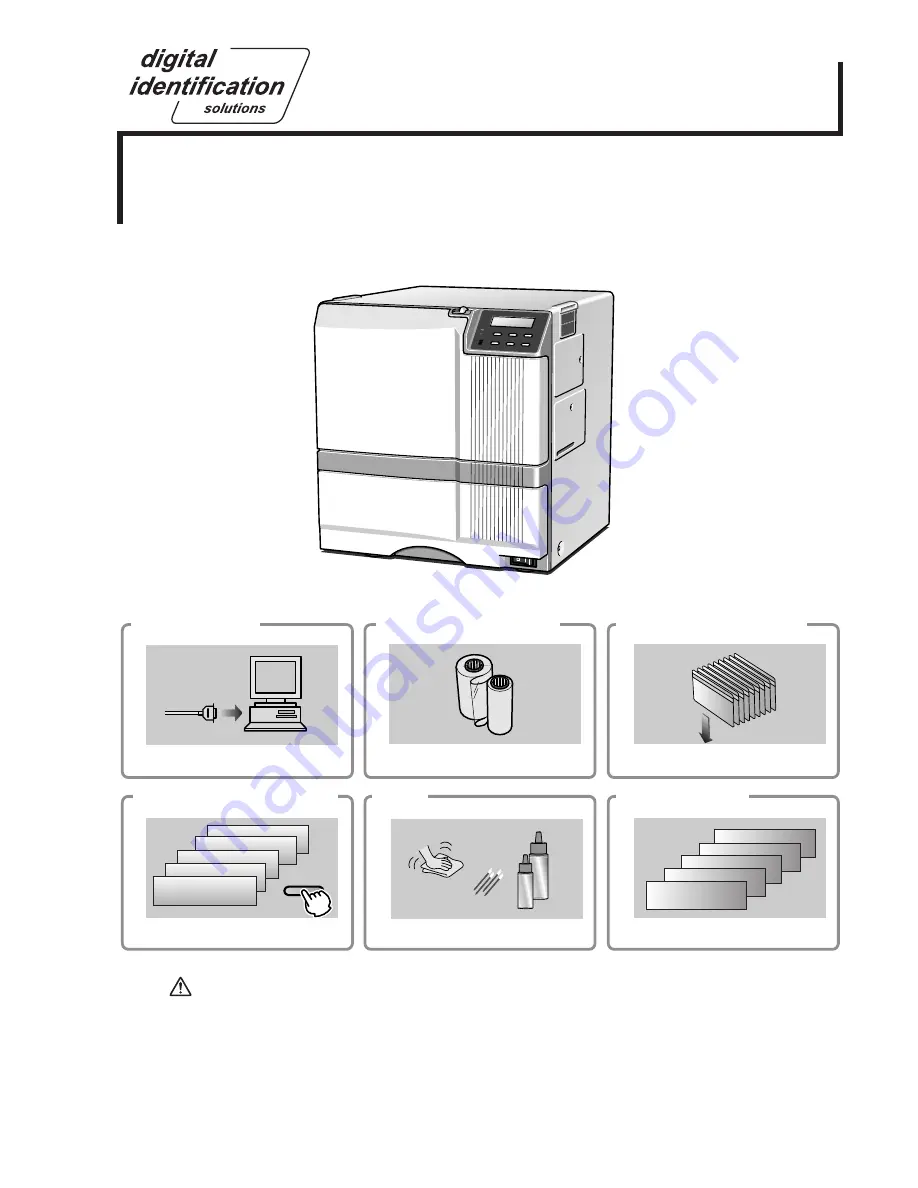

Instruction Manual

Sublimation type retransfer printer

Error codes

Setting the cards

Care

Operation and Setting the various modes

Ink replacement

Connection

* * *

Model

X

ID5xxie Retransfer Printer

EDI

secure

®

See p.11~12,21

See p.14~18

See p.18~20

See p.25~39

See p.40~44

See p.46~47

•

Thank for purchasing this product.

•

Please read this manual carefully

before use to ensure correct operation.

It is particularly important to read the Safety Precautions

for safe operation. After

reading, retain this manual carefully for future reference.

•

The product number is important for quality control. Upon purchase, check the back of

the unit to make sure that the product number is correctly displayed.

Notes about this manual

(1) This manual may not be reprinted in any way without permission.

(2) The contents of this manual, as well as the specifications and design of this product,

may change without notice.

(3) The illustrations used in this manual may differ slightly from the actual product.